Mold Factory

Plastic molding shrinkage ratePlastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are show...More+

Plastic molding shrinkage ratePlastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are show...More+

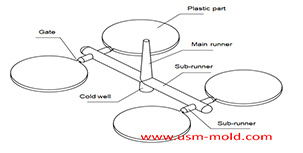

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

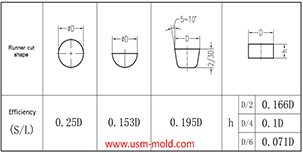

Hydraulic diameter conversion of runners in plastic mold gating system designHydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls, on...More+

Hydraulic diameter conversion of runners in plastic mold gating system designHydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls, on...More+

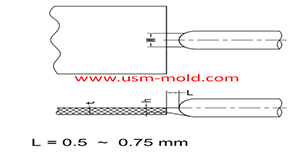

Plastic injection mold runner system designThe gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate dir...More+

Plastic injection mold runner system designThe gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate dir...More+

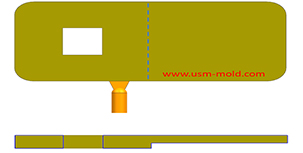

Gate position determination of plastic injection mold runner design systemIn the selection of gate location, the following issues should be paid attention to:1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt flows...More+

Gate position determination of plastic injection mold runner design systemIn the selection of gate location, the following issues should be paid attention to:1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt flows...More+

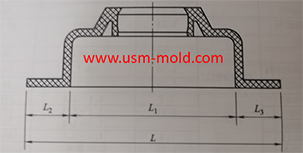

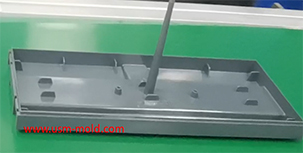

Direct gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Direct gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

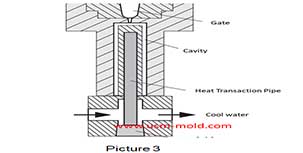

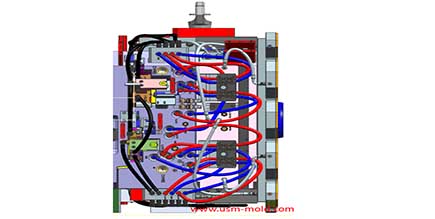

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

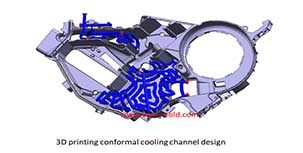

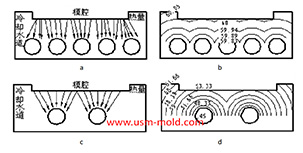

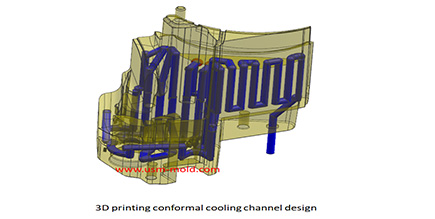

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

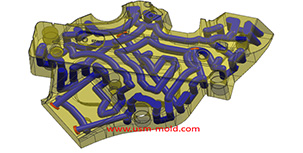

Plastic injection mold cooling system design noticeDesign notice of designing the cooling system:1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;2. U...More+

Plastic injection mold cooling system design noticeDesign notice of designing the cooling system:1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;2. U...More+

English

English русский

русский