Blog

- 1105, 2024

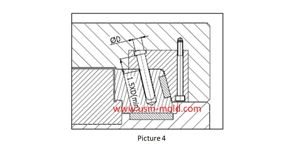

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...More

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...More - 2304, 2024

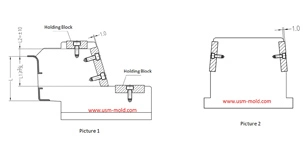

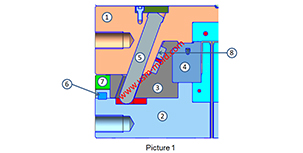

Slider spring hength and strength calculationProcessing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...More

Slider spring hength and strength calculationProcessing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...More - 301, 2024

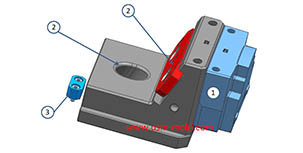

The design requirements of slider wear plate1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...More

The design requirements of slider wear plate1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...More - 1912, 2023

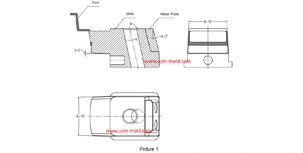

The T slot of slider and guider designing tips1. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...More

The T slot of slider and guider designing tips1. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...More - 512, 2023

Slider angle designing tipsTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |1. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...More

Slider angle designing tipsTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |1. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...More - 2311, 2023

Slider designing tips 2Tags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Injection Molding Supplier | Mold Factory | Mold Supplier | Injection Molding |9. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...More

Slider designing tips 2Tags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Injection Molding Supplier | Mold Factory | Mold Supplier | Injection Molding |9. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...More - 408, 2022

Slider designing tips 1Tags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Injection Molding Supplier | Injection Molding Factory | Mold Factory | Mold Supplier | Injection Molding |1. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...More

Slider designing tips 1Tags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Injection Molding Supplier | Injection Molding Factory | Mold Factory | Mold Supplier | Injection Molding |1. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...More - 2207, 2022

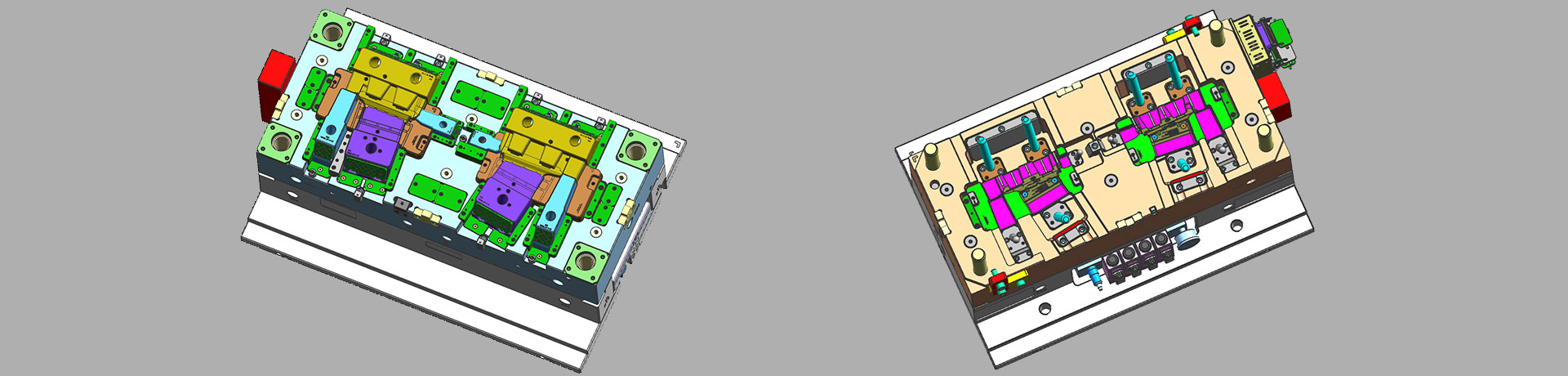

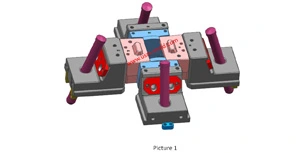

Slider of side core pulling mechanisum assemblingTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Injection Molding Supplier | Injection Molding Factory | Mold Factory | Mold Supplier | Injection Molding |The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...More

Slider of side core pulling mechanisum assemblingTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Injection Molding Supplier | Injection Molding Factory | Mold Factory | Mold Supplier | Injection Molding |The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...More

English

English русский

русский