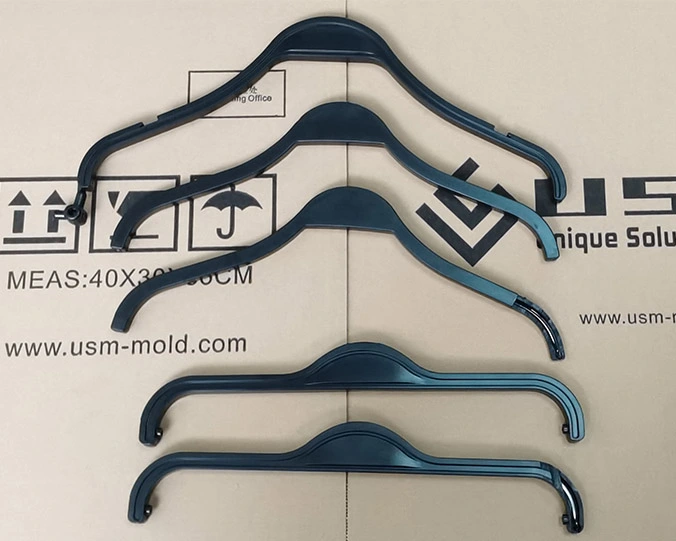

gas assisted injection molding process

Visual Doorbell Housing MoldLighting control can adjust the lighting of all rooms by pressing a few buttons, the scene function can realize various scene modes, and the full turn on and off function can realize the one-key to turn on and off functions of all lamps and lanterns.More+

Visual Doorbell Housing MoldLighting control can adjust the lighting of all rooms by pressing a few buttons, the scene function can realize various scene modes, and the full turn on and off function can realize the one-key to turn on and off functions of all lamps and lanterns.More+

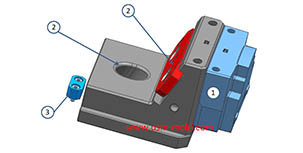

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Medical Mold Injection ProductMedical devices have strict standards for molds, mainly involved in mold design, mold steel, manufacturing accuracy, sanitary production conditions, and transportation condition and many other aspects.More+

Medical Mold Injection ProductMedical devices have strict standards for molds, mainly involved in mold design, mold steel, manufacturing accuracy, sanitary production conditions, and transportation condition and many other aspects.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

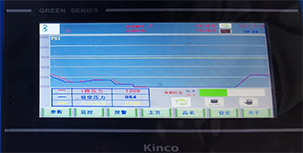

Key points of gas-assisted injection molding processGas injection parametersThe gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas i...More+

Key points of gas-assisted injection molding processGas injection parametersThe gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas i...More+

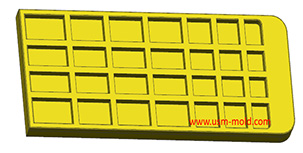

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

English

English русский

русский