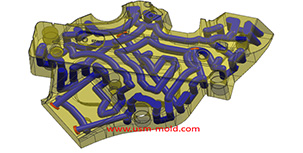

gas assisted injection molding process

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

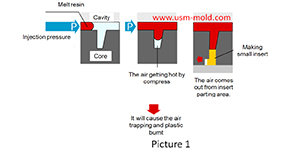

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

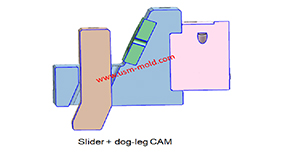

Classification of side parting and core pulling mechanismAccording to the structural characteristics, the side core-pulling mechanisms are divided into the following six categories:1. The side core-pulling mechanism of "slider + guide pin";2. The ...More+

Classification of side parting and core pulling mechanismAccording to the structural characteristics, the side core-pulling mechanisms are divided into the following six categories:1. The side core-pulling mechanism of "slider + guide pin";2. The ...More+

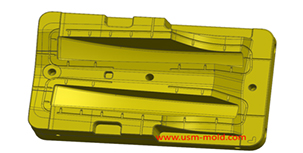

Drip Tip MoldThe two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.More+

Drip Tip MoldThe two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

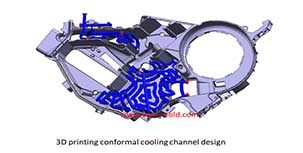

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

English

English русский

русский