The design principle of the exhaust slot

The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality, especially for predeformation mold, the part size will be different if there is air trapping inside mold, which will cause instability during production.

We must follow the following principles when making the mold exhaust slot:

1. The exhaust must be rapid and complete, and the exhaust speed should be compatible with the filling speed;

2. The exhaust slot (hole) should be made in thicker wall thickness of the plastic part;

3. The exhaust slot should be made in parting surface as much as possible, and it is better to make it on the side of the cavity side(according to the shape, characteristics and mold structure of the plastic part, the position of the exhaust slot is allowed to make in core side);

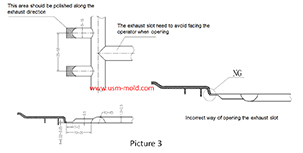

4. The burrs generated by the overflow of the exhaust slot should not hinder the demolding;

5. The exhaust slot should be made as far as possible at the end of the material flow, such as the end of the runner and slug well ;

6. The exhaust direction of the exhaust slot should be toward the reverse operation surface;

7. Refer to the standard data for the depth of the exhaust slot and the depth of the overflow slot, the width and distance, etc.;

8. The exhaust slot should be polished along the exhaust direction;

9. Exhaust slot must be made at the weld mark area;

10. It is better to make the exhaut slot as deep as possible which can not see the flash, but it will be better to see the flash in runner area.

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

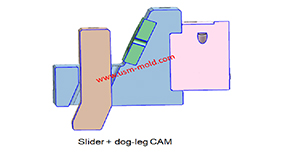

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

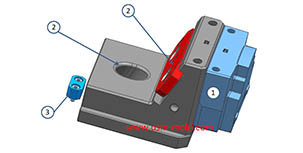

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

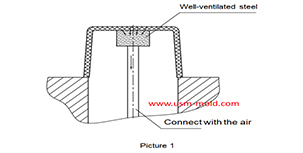

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view

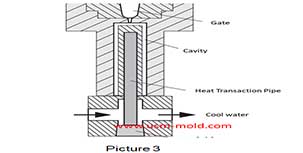

Plastic injection mold common cooling gate

Feb 17, 20221. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing....view

English

English русский

русский