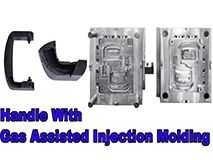

gas assisted injection molding factory

Water assisted injection molding introductionLike the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic b...More+

Water assisted injection molding introductionLike the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic b...More+

Overmolding & 2k MoldingMaterial selection for two-color products: The same type of material of different colors is usually used for two-color injection molding so that the bonding strength of the first color and the second color plastic is the best.More+

Overmolding & 2k MoldingMaterial selection for two-color products: The same type of material of different colors is usually used for two-color injection molding so that the bonding strength of the first color and the second color plastic is the best.More+

- Privacy PolicyThis Privacy Policy applies to the worldwide websites of which is part of the Sunkye International. It explains how we collect, process, share, secure and store personal information (information and ...More+

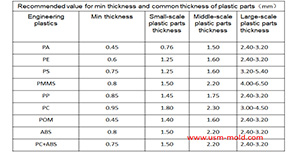

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

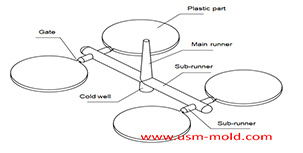

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

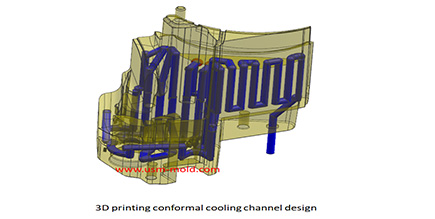

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

English

English русский

русский