Water assisted injection molding introduction

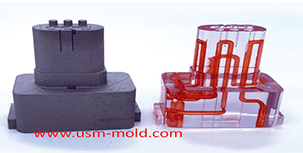

Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic back and force the workpiece to form a hollow state. Research and applications have shown that water-assisted parts can make thinner and more even wall thickness parts which means material savings. In addition, comparing to gas-assisted injection molding, water-assisted injection molding can produce larger and smoother inner walls. Comparing with gas-assisted injection molding with nitrogen, the main advantage of water-assisted injection is the rapid cooling efficiency of water, the thermal conductivity of water is 40 times higher than nitrogen, and the heat capacity of water is 4 times larger than gas. For thick-wall parts, the cooling time of water-assisted and gas-assisted can be reduced by 30-70%. The main difference between gas and water is that gas can be compressed but water cannot. The higher viscosity and incompressibility of water make the front end of the water form a solid interface, which acts as a squeezing hammer to hollow out the workpiece, the front side of water also serves to cool the melt filled into the cavity and core.

.png)

The main difference between water and gas is that gas is compressible but the water is not. because of the viscosity and incompressibility of water relative to gas that water can play a role in hollow molding. When the water is injected in a way that the water will not evaporate during the injection, the front side of the water acts like a moving plunger on the melt center of the part. from the front side of the water to the transition section of the melt, the plastic with a thin solidified layer membrane, it is like a high-viscosity core to further push the polymer melt, thereby hollowing out the part, while the water pressure pushes it forward, the water also cools the melt, the gravity or compressed air is used to drain the water from the workpiece and flow into a storage tank fat the end, where the water can be recycled. Water injection moulding can greatly shorten the molding cycle of products, and can be used to produce lightweight and strong hollow products with good appearance effects.

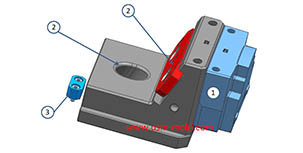

Slider designing tips 1

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

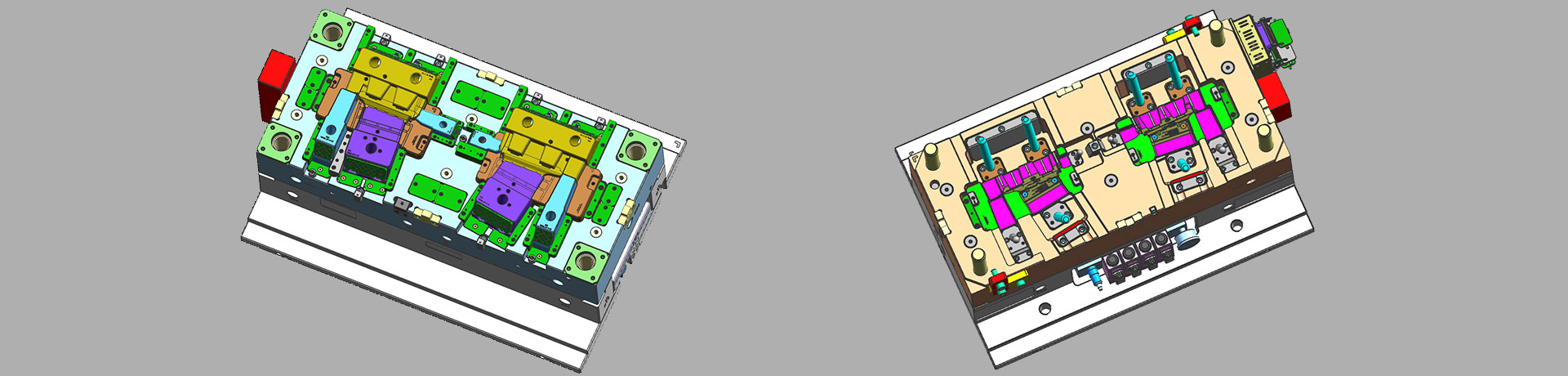

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

The principle of mold temperature balance in plastic mold cooling system design

Feb 21, 2022The principle of mold temperature balance: 1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

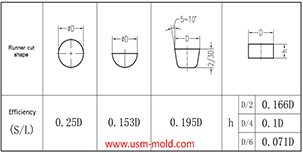

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

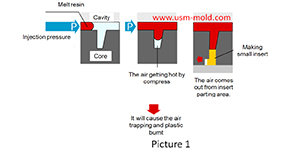

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

English

English русский

русский