gas assisted injection molding factory

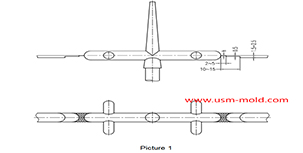

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

- HomeEstablished in the year of 1996, HanKing start the business in mould making and injection molding in Longgang, Shenzhen, after years development, we have become a one-stop total plastic solution pr...More+

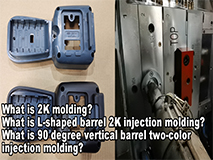

What is 2K molding? What is L-shaped barrel two-color injection molding? What is 90-degree vertical barrel two-color injection molding?More+

What is 2K molding? What is L-shaped barrel two-color injection molding? What is 90-degree vertical barrel two-color injection molding?More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

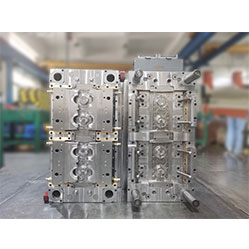

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Water Assisted Injection MouldBecause the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.More+

Water Assisted Injection MouldBecause the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.More+

PLC Controller Shell MoldMore and more people will have a high standard for a better life, most of home appliance product surfaces were made by mirror polishing, it requires for high standard to mold steel and polishing way, good mold steel without a technical polishing engineer, the product can not reach the high standard, they always work together.More+

PLC Controller Shell MoldMore and more people will have a high standard for a better life, most of home appliance product surfaces were made by mirror polishing, it requires for high standard to mold steel and polishing way, good mold steel without a technical polishing engineer, the product can not reach the high standard, they always work together.More+

English

English русский

русский