gas assisted injection molding factory

Venting system of plastic injection mold introductionHello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the reas...More+

Venting system of plastic injection mold introductionHello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the reas...More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Plastic Household MouldAdvantages of Smart Home Appliance MoldMeet different demandsIn order to meet the different types of demands, grades, and styles, the control host of the smart home system can also be upgraded online.More+

Plastic Household MouldAdvantages of Smart Home Appliance MoldMeet different demandsIn order to meet the different types of demands, grades, and styles, the control host of the smart home system can also be upgraded online.More+

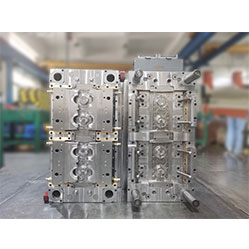

Automotive Door MoldThe plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.More+

Automotive Door MoldThe plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

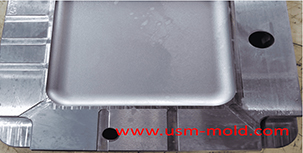

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

TV Frame MoldPushing the liquid plastic into the cavity and core side by high pressure during the injection process, and the gas pressure is maintained to form a hollow section inside the thick wall of the plastic part, the injection process is called gas-assisted injection molding.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский