gas assisted injection molding

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

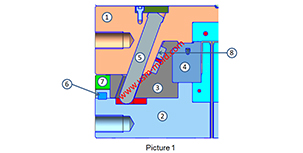

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

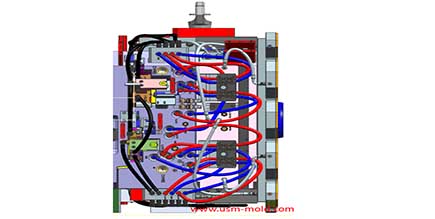

Plastic injection mold cooling system design noticeDesign notice of designing the cooling system:1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;2. U...More+

Plastic injection mold cooling system design noticeDesign notice of designing the cooling system:1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;2. U...More+

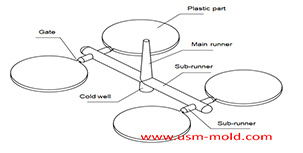

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

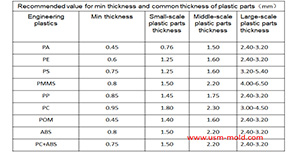

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Venting system of plastic injection mold introductionHello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the reas...More+

Venting system of plastic injection mold introductionHello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the reas...More+

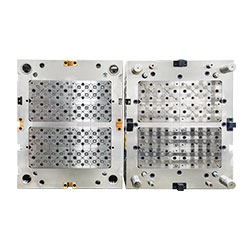

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

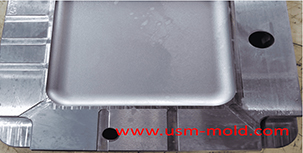

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

English

English русский

русский