gas assisted injection molding

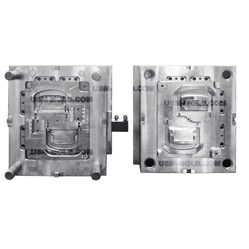

Car Ceiling Handle Injection MouldWhen plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.More+

Car Ceiling Handle Injection MouldWhen plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.More+

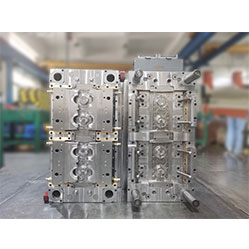

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

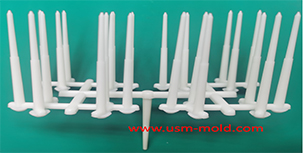

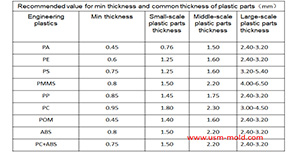

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

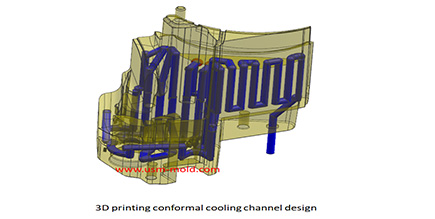

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

- Leading manufacturers of plastic injection mould and molded parts.We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K molding and other industrial parts.More+

English

English русский

русский