gas assisted injection molding supplier

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

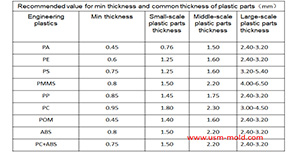

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Design principles for wall thickness of plastic productsThe principles of wall thickness design for plastic parts are as follows:1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking eve...More+

Water assisted injection molding introductionLike the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic b...More+

Water assisted injection molding introductionLike the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic b...More+

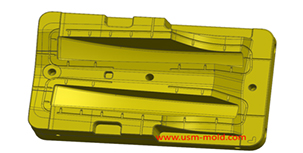

Automotive AC Air OutletThe air outlets of automotive AC are generally assembled by multiple parts, classified according to their functions and purposes: there are exterior molds, functional molds, or both exterior and functional molds.More+

Automotive AC Air OutletThe air outlets of automotive AC are generally assembled by multiple parts, classified according to their functions and purposes: there are exterior molds, functional molds, or both exterior and functional molds.More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

Medical Mold Injection ProductMedical devices have strict standards for molds, mainly involved in mold design, mold steel, manufacturing accuracy, sanitary production conditions, and transportation condition and many other aspects.More+

Medical Mold Injection ProductMedical devices have strict standards for molds, mainly involved in mold design, mold steel, manufacturing accuracy, sanitary production conditions, and transportation condition and many other aspects.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

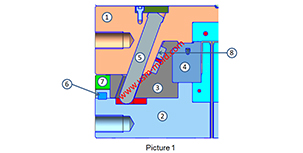

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

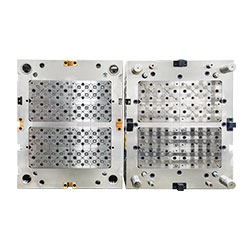

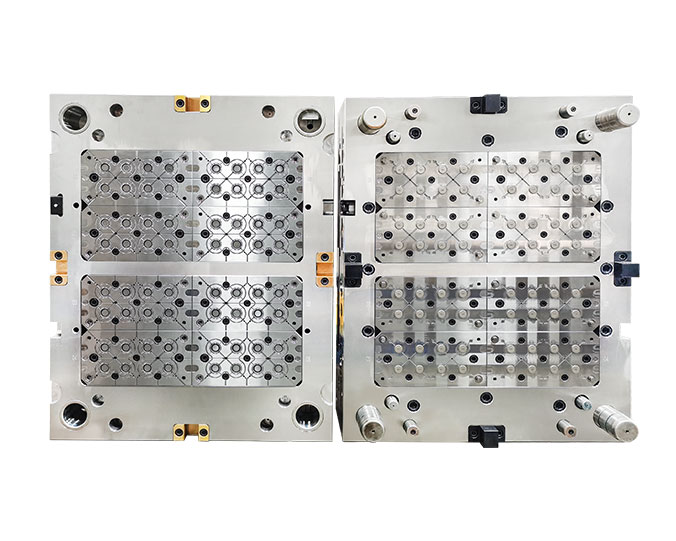

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

English

English русский

русский