gas assisted injection molding supplier

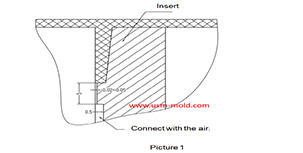

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

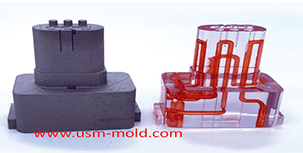

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

USM Purchased Two New Sodick Edm EquipmentsUSM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.More+

USM Purchased Two New Sodick Edm EquipmentsUSM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.More+

Parallel barrel 2K injectionWhat is parallel barrel (2K) two-shot injection molding? What is 2K injection molding? Let’s see the what is called parallel barrel 2K injection molding. The injection molding machine used for...More+

Parallel barrel 2K injectionWhat is parallel barrel (2K) two-shot injection molding? What is 2K injection molding? Let’s see the what is called parallel barrel 2K injection molding. The injection molding machine used for...More+

Plastic Switch MouldUSM is an ISO9001:2015 certified mold and injection molding factory. It has its own unique solutions from smart home appliance product development for mold design, mold manufacturing, and injection molding production.More+

Plastic Switch MouldUSM is an ISO9001:2015 certified mold and injection molding factory. It has its own unique solutions from smart home appliance product development for mold design, mold manufacturing, and injection molding production.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

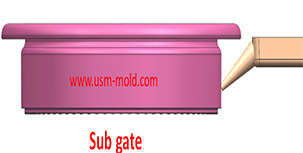

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

The sub gate of the plastic injection mold runner systemIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

Metal Insert MoldFor rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.More+

English

English русский

русский