gas assisted injection molding supplier

- Success factors of USMThe ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time and competitive priceMore+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

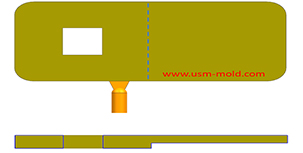

Gate position determination of plastic injection mold runner design systemIn the selection of gate location, the following issues should be paid attention to:1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt flows...More+

Gate position determination of plastic injection mold runner design systemIn the selection of gate location, the following issues should be paid attention to:1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt flows...More+

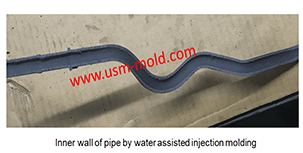

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

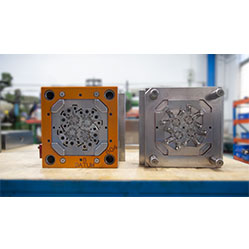

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

USM Purchased Two New Sodick Edm EquipmentsUSM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.More+

USM Purchased Two New Sodick Edm EquipmentsUSM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

English

English русский

русский