gas assisted injection molding process

3 Precision Molds Are Ready to Ship GermanyAfter 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.More+

3 Precision Molds Are Ready to Ship GermanyAfter 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.More+

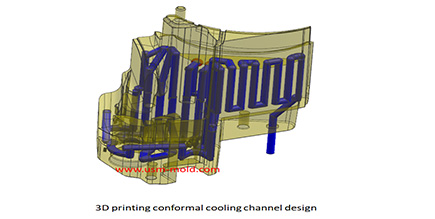

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

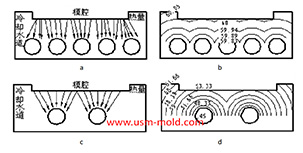

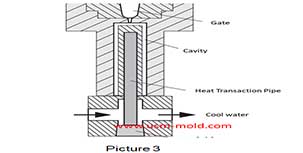

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

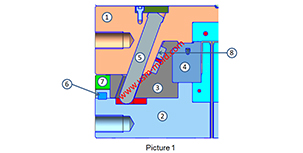

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

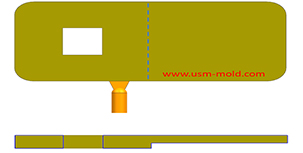

Gate position determination of plastic injection mold runner design systemIn the selection of gate location, the following issues should be paid attention to:1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt flows...More+

Gate position determination of plastic injection mold runner design systemIn the selection of gate location, the following issues should be paid attention to:1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt flows...More+

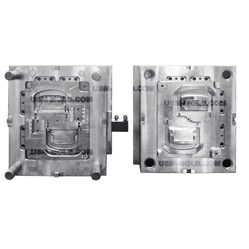

Car Ceiling Handle Injection MouldWhen plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.More+

Car Ceiling Handle Injection MouldWhen plastic injection molding, the melt is under the injection pressure and enters the mold cavity, on the same section, the flow rate of each gate is different, the fastest in the middle, the closer to the cavity wall, the slower the flow rate, and it contacts the cavity wall, the speed of the first layer is zero.More+

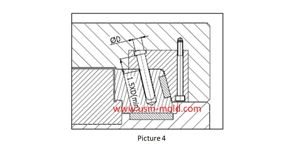

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following:1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, a...More+

The common fixing method of angle pinThe angle pin is a common part of the drive slider, and the fixing and installation methods as following:1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, a...More+

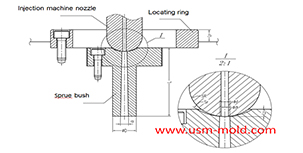

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

- HomeEstablished in the year of 1996, HanKing start the business in mould making and injection molding in Longgang, Shenzhen, after years development, we have become a one-stop total plastic solution pr...More+

English

English русский

русский