gas assisted injection molding plastic parts

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

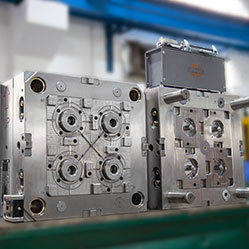

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

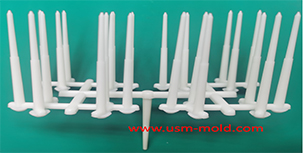

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Dongguan International Machine Tool Exhibition of 2021 hedling successfully2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry.More+

Dongguan International Machine Tool Exhibition of 2021 hedling successfully2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry.More+

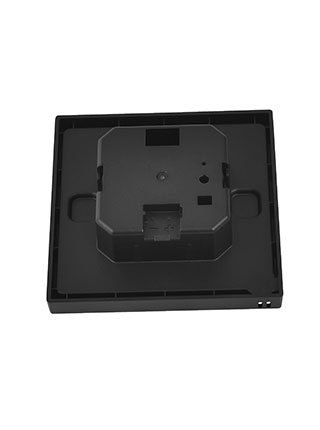

_20250317101516A021.jpg) The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

The basic points of designing gas-assisted injection molding1. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel;2. The gas channel should be arranged in balan...More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

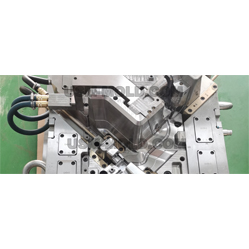

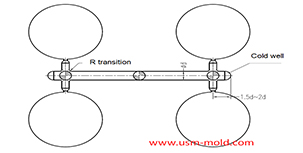

Key points of plastic injection mold runner systemThe sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More+

Key points of plastic injection mold runner systemThe sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More+

English

English русский

русский