gas assisted injection molding plastic parts

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

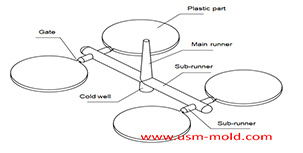

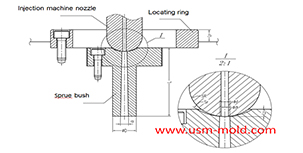

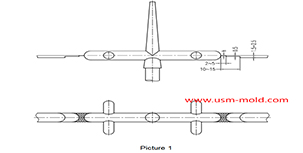

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

The main design points of the design of the plastic mold pouring systemThe main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision w...More+

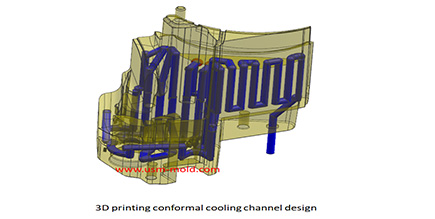

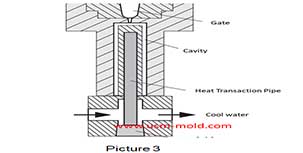

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

English

English русский

русский