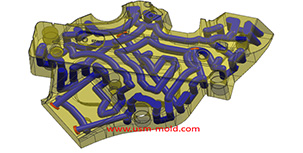

gas assisted injection molding moldflow

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

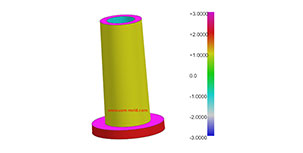

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

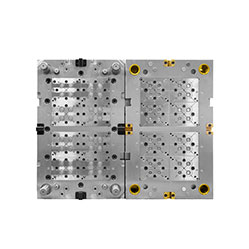

Multi Cavity Medical MoldMedical equipment products are divided into many different types, some products do not contact the human body, some contact the human body, some enter the body, and some products need to pass the FDA Alcohol test, some have to pass the FDA n-ethane test.More+

Multi Cavity Medical MoldMedical equipment products are divided into many different types, some products do not contact the human body, some contact the human body, some enter the body, and some products need to pass the FDA Alcohol test, some have to pass the FDA n-ethane test.More+

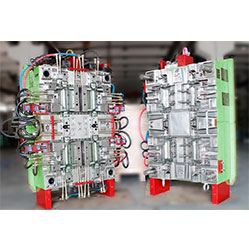

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

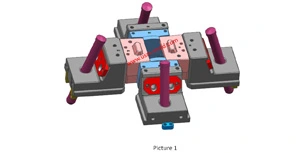

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

Water Tank MouldThe mold will be made welding process many times during modification, but it will reduce the accuracy and mold life a lot. some factories might use the normal steel to make manufacturing and then make real mold manufacturing after the first prototype mold work well, but it also influences the mold cost and delivery time.More+

English

English русский

русский