gas assisted injection molding moldflow

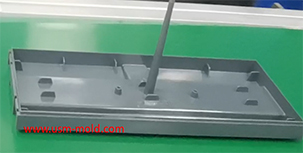

Touch Switch Sensor MoldConvenience, comfort, artistry, and realize an environmentally friendly and energy-saving living environment.More+

Touch Switch Sensor MoldConvenience, comfort, artistry, and realize an environmentally friendly and energy-saving living environment.More+

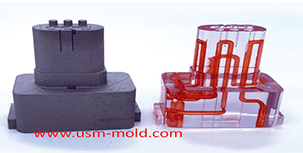

Water Assisted Injection MouldBecause the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.More+

Water Assisted Injection MouldBecause the flow rate of the outer layer of the melt is slow and the speed of the inner layer is fast, the inner layer of melt will roll outwards and stick to the mold cavity while advancing.More+

Direct gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Direct gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Mold ManufacturingUSM is a one-stop service for plastic precision mold and injection molding factory in China, as we know, perfect molds are related to professional mold design, high precision processing machines, rich experiences assembling workers, and team management.More+

Mold ManufacturingUSM is a one-stop service for plastic precision mold and injection molding factory in China, as we know, perfect molds are related to professional mold design, high precision processing machines, rich experiences assembling workers, and team management.More+

Auto Parts MouldThe automotive console is an external part in automotive interior parts, and no weld line on the part surface, the console's gating system generally uses a valve gate of hot runner system, the gate position usually has a direct injection gate on the non-critical surface which is to save plastic material, the shut-off area will be injected on side of the non-critical surface, or the middle area will be injected to the non-critical surface by the banana gate.More+

Auto Parts MouldThe automotive console is an external part in automotive interior parts, and no weld line on the part surface, the console's gating system generally uses a valve gate of hot runner system, the gate position usually has a direct injection gate on the non-critical surface which is to save plastic material, the shut-off area will be injected on side of the non-critical surface, or the middle area will be injected to the non-critical surface by the banana gate.More+

Unique Solutions Mold ProfileUSM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square meters.More+

Unique Solutions Mold ProfileUSM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square meters.More+

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

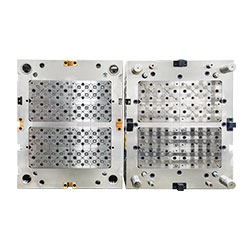

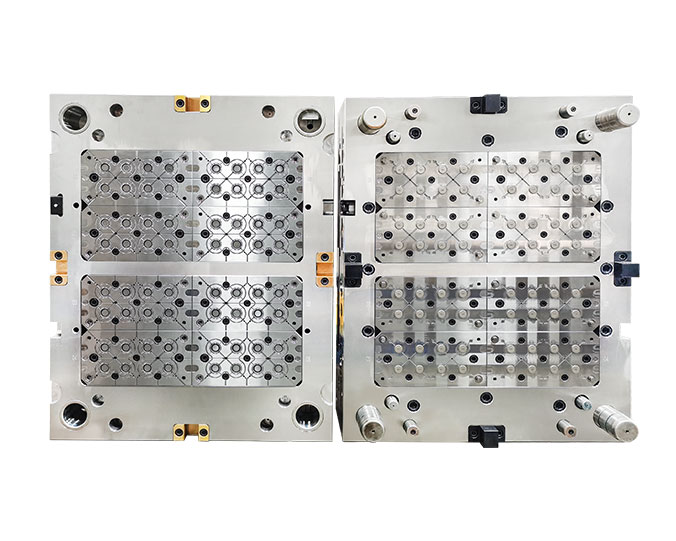

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

Multi Cavity MoldMulti cavity mold requires very high machining accuracy. if the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.More+

English

English русский

русский

_20250317101606A022.jpg)