gas assisted injection molding moldflow

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

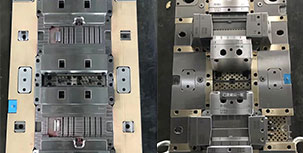

What is Plastic Injection Mold?The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and sizes.More+

What is Plastic Injection Mold?The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and sizes.More+

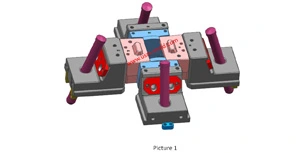

_20250317101937A023.jpg) What is the side parting and core pulling mechanisms with their function?When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...More+

What is the side parting and core pulling mechanisms with their function?When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Air Chamber MoldWith over 15 years of pre-deformed mold, USM Mold has mastered scientific and complete pre-deformation mold technology, from project management, mold flow analysis, design, manufacturing, assembling, mold trial, and final measurement.More+

Air Chamber MoldWith over 15 years of pre-deformed mold, USM Mold has mastered scientific and complete pre-deformation mold technology, from project management, mold flow analysis, design, manufacturing, assembling, mold trial, and final measurement.More+

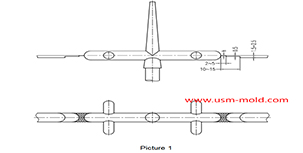

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

Parting surface venting of runner systemThere are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting s...More+

English

English русский

русский

_20250317101516A021.jpg)