gas assisted injection molding moldflow

Gas-assisted injection molding of kettle handlesWhat is the gas-assisted injection molding? Today we will talk about the case of gas-assisted injection molding of kettle handles. During the injection molding process, push the melt plastic to fi...More+

Gas-assisted injection molding of kettle handlesWhat is the gas-assisted injection molding? Today we will talk about the case of gas-assisted injection molding of kettle handles. During the injection molding process, push the melt plastic to fi...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

Plastic injection mold heatingWhen the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplast...More+

- Find UsCustom injection mold manufacturing and plastic injection molding in China.Address: No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, ChinaTel: 86-0769-8539 0209Email: [email protected]...More+

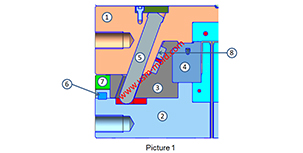

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

Slider of side core pulling mechanisum assemblingThe picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.1. Lateral forming parts...More+

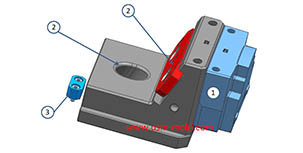

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

What is 2K molding? What is L-shaped barrel two-color injection molding? What is 90-degree vertical barrel two-color injection molding?More+

What is 2K molding? What is L-shaped barrel two-color injection molding? What is 90-degree vertical barrel two-color injection molding?More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

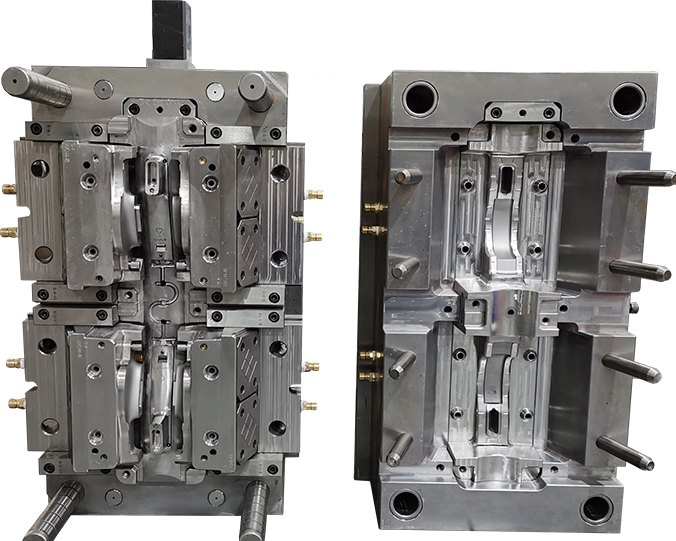

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

English

English русский

русский