gas assisted injection molding moldflow

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

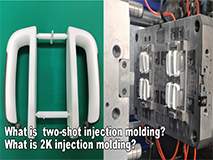

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

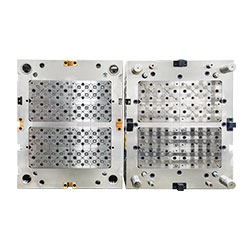

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

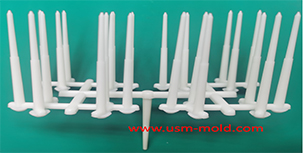

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Automotive MoldAutomotive Molds Characteristics1. The automotive mold size is very big, and the largest mold weight is nearly 40T;2. The mold structure is complex;3. There are many irregular curved surfaces on the parting surface.More+

Automotive MoldAutomotive Molds Characteristics1. The automotive mold size is very big, and the largest mold weight is nearly 40T;2. The mold structure is complex;3. There are many irregular curved surfaces on the parting surface.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

English

English русский

русский