gas assisted injection molded products

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

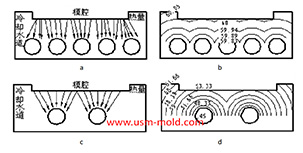

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

3 Precision Molds Are Ready to Ship GermanyAfter 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.More+

3 Precision Molds Are Ready to Ship GermanyAfter 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Five Major Steps of the Injection Mold Production ProcessInjection mold manufacturing can be roughly divided into the following steps:Process analysis of plastic products.More+

Overmolding & 2k MoldingMaterial selection for two-color products: The same type of material of different colors is usually used for two-color injection molding so that the bonding strength of the first color and the second color plastic is the best.More+

Overmolding & 2k MoldingMaterial selection for two-color products: The same type of material of different colors is usually used for two-color injection molding so that the bonding strength of the first color and the second color plastic is the best.More+

English

English русский

русский