gas assisted injection molded products

Limitations of gas-assisted injection molding technologyGas-assisted injection molding technology has obvious advantages in thick wall thicknes and tpipe parts, but this technology still has many limitations, which are mainly reflected in the following asp...More+

Limitations of gas-assisted injection molding technologyGas-assisted injection molding technology has obvious advantages in thick wall thicknes and tpipe parts, but this technology still has many limitations, which are mainly reflected in the following asp...More+

Gas-assisted injection molding of kettle handlesWhat is the gas-assisted injection molding? Today we will talk about the case of gas-assisted injection molding of kettle handles. During the injection molding process, push the melt plastic to fi...More+

Gas-assisted injection molding of kettle handlesWhat is the gas-assisted injection molding? Today we will talk about the case of gas-assisted injection molding of kettle handles. During the injection molding process, push the melt plastic to fi...More+

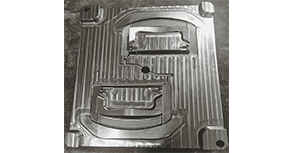

Voice Operated Switch MoldWe know that the basic goal of smart home appliances is to provide people with a comfortable, safe, convenient and efficient living environment. Therefore, the most important thing for smart home appliance products is to take practicality as the core, remove those flashy functions, and use practicality, ease of use, and humanization.More+

Voice Operated Switch MoldWe know that the basic goal of smart home appliances is to provide people with a comfortable, safe, convenient and efficient living environment. Therefore, the most important thing for smart home appliance products is to take practicality as the core, remove those flashy functions, and use practicality, ease of use, and humanization.More+

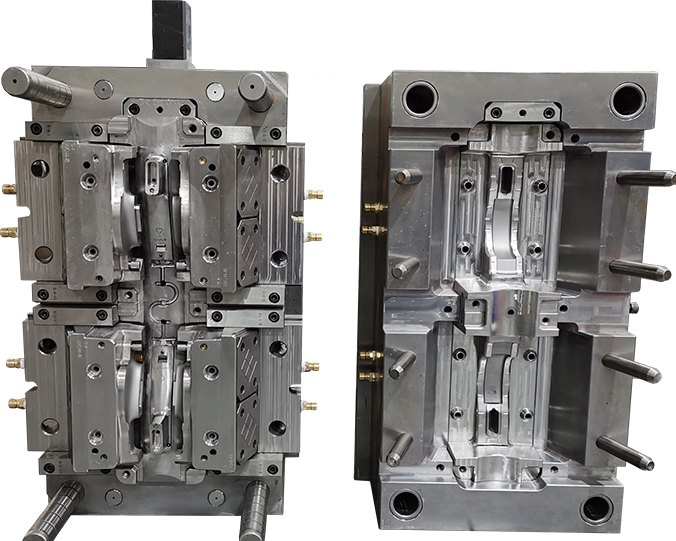

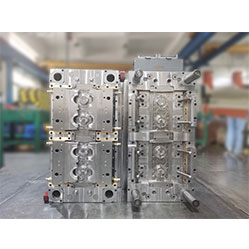

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

Dongguan International Machine Tool Exhibition of 2021 hedling successfully2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry.More+

Dongguan International Machine Tool Exhibition of 2021 hedling successfully2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry.More+

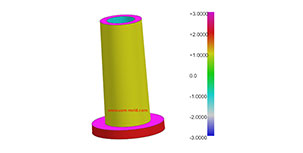

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

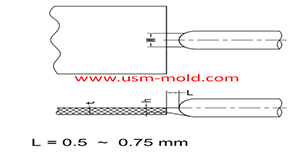

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Banana gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

English

English русский

русский