gas assisted injection mold supplier

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

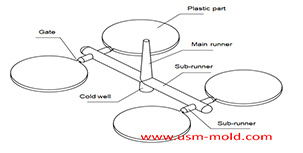

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

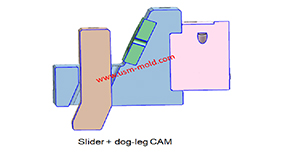

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

Slider designing tips 2The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;When u...More+

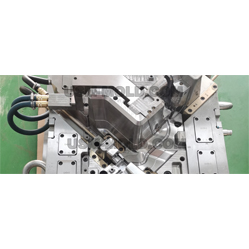

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

USM Blogo OpeningHello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.More+

English

English русский

русский