gas assisted injection mold supplier

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Design Tips of Vacuum Venting MoldThere are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm ma...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Limitations of gas-assisted injection molding technologyGas-assisted injection molding technology has obvious advantages in thick wall thicknes and tpipe parts, but this technology still has many limitations, which are mainly reflected in the following asp...More+

Limitations of gas-assisted injection molding technologyGas-assisted injection molding technology has obvious advantages in thick wall thicknes and tpipe parts, but this technology still has many limitations, which are mainly reflected in the following asp...More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

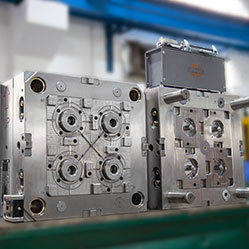

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

4 Cavity MoldA multi-cavity mold means that multiple identical parts are made in one set mold, and multiple identical parts can be produced in one injection cycle at the same time.More+

- HomeEstablished in the year of 1996, HanKing start the business in mould making and injection molding in Longgang, Shenzhen, after years development, we have become a one-stop total plastic solution pr...More+

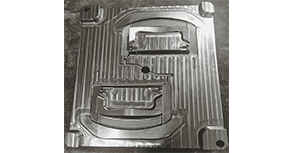

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

Automotive Window Frame MouldUSM has 15 years of experience in pre-deformed mold designing, From the mold flow analysis to get theoretical deformation amount, and then make Crim's test by UDB material file which used to obtain the actual deformation amount, then leave enough space for steel when mold design according to professional experience in order to shorten the modification time and longer mold life.More+

English

English русский

русский