gas assisted injection mold supplier

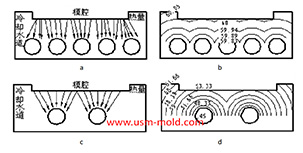

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

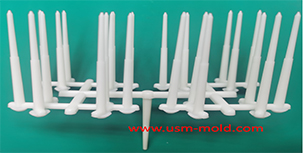

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

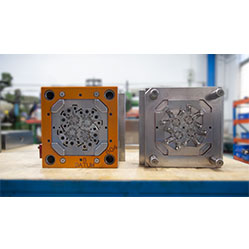

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

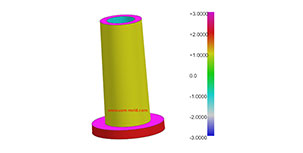

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

What is Called Draft Angle?The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in pictureMore+

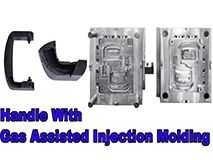

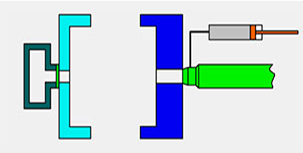

The difference between full shot and short shot of gas-assisted injection moldingGas-assisted injection molding can be divided into short shot and full shot.Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filli...More+

The difference between full shot and short shot of gas-assisted injection moldingGas-assisted injection molding can be divided into short shot and full shot.Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filli...More+

Plastic Household MouldAdvantages of Smart Home Appliance MoldMeet different demandsIn order to meet the different types of demands, grades, and styles, the control host of the smart home system can also be upgraded online.More+

Plastic Household MouldAdvantages of Smart Home Appliance MoldMeet different demandsIn order to meet the different types of demands, grades, and styles, the control host of the smart home system can also be upgraded online.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

Insert Mold PartsInsert molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.More+

English

English русский

русский