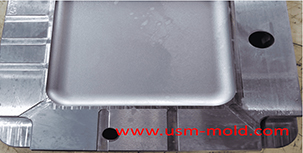

Automotive ceiling handle mold

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

3 Precision Molds Are Ready to Ship GermanyAfter 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.More+

3 Precision Molds Are Ready to Ship GermanyAfter 2 months later, the 3 molds have been finished and ready to ship. From DFM report to mold design to manufacturing and T1 samples were provided in 6 weeks.More+

Automotive Door MoldThe plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.More+

Automotive Door MoldThe plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.More+

_20250317101606A022.jpg) Several common process of water-assisted injection molding introductionAccording to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...More+

Several common process of water-assisted injection molding introductionAccording to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...More+

Venting system of plastic injection mold introductionHello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the reas...More+

Venting system of plastic injection mold introductionHello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the reas...More+

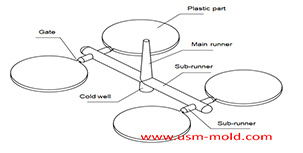

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

Design principles of plastic injection mold runner system1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More+

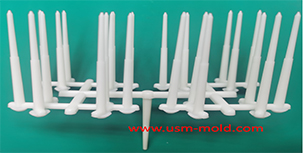

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Pin-point gate of plastic injection mold runner system designIn order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among ...More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

English

English русский

русский