0769-8539-0209

/

+86-15158220988

According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories:

1. The side core-pulling mechanism of "slider + guide pin";

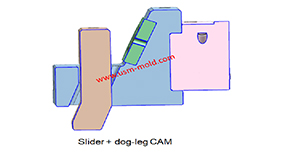

2. The side core-pulling mechanism of "slider +dog-leg CAM";

3. The side core-pulling mechanism of "slider + T-block";

4. The side core-pulling mechanism of slider + hydraulic cylinder;

5. Side core pulling mechanism of lifter;

6. side core pulling mechanism of side slider.