The difference between full shot and short shot of gas-assisted injection molding

Gas-assisted injection molding can be divided into short shot and full shot.

- Short shot

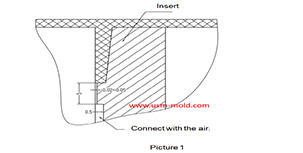

The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling resistance, especially rod-shaped parts, which can save a lot of raw material, we should inject part of resin into the cavity and core (usually only fills 50% volume of caity and core) during the short shot, and immediately inject gas into the center of the resin, push the gas and obtain a hollow plastic part, For thin-walled plastic parts with high mold filling resistance, it’s better to use full shot molding.

For short shots, the percentage and prolong time of plastic melt fills the cavity and core before the gas injected are the main factors to control the length of the gate channel, in addition, the further shrinkage of the plastic will make the channel continue to be longer, if too much plastic is injected at early stage, it will cause the gas flow length is not enough, but if too little plastic is injected, the gas will quickly penetrate the plastic flow front and cause waste.

2. Sub-cavity method (full shot)

The secondary cavity molding method, it is also called the overflow well method, it is a kind of full shot process (as shown in picture 2). the secondary cavity method requires a secondary cavity that can connect with the mold cavity in outside, the secondary cavity follows the main cavity, the valve needle between the cavities is opened or closed by the hydraulic cylinder or air cylinder, first, close the sub cavity, inject plastic melt into the cavity until the cavity and core is full, then open the sub cavity, and inject gas into the cavity, the penetration of gas pressure causes the excess melt to flow into the secondary cavity, when the gas penetrates to a certain extent, the secondary cavity is closed, and the gas pressure continues to increase to maintain pressure and feed the melt in the cavity with core side, and finally open the mold to eject products.

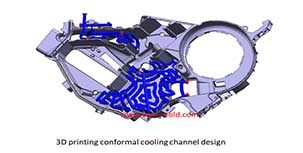

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

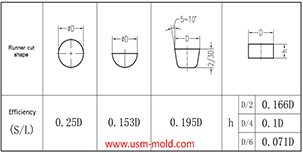

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

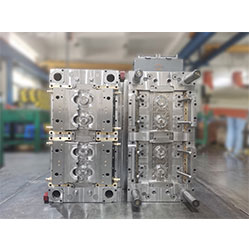

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

English

English русский

русский

_20250310164515A048.webp)