Design Tips of Vacuum Venting Mold

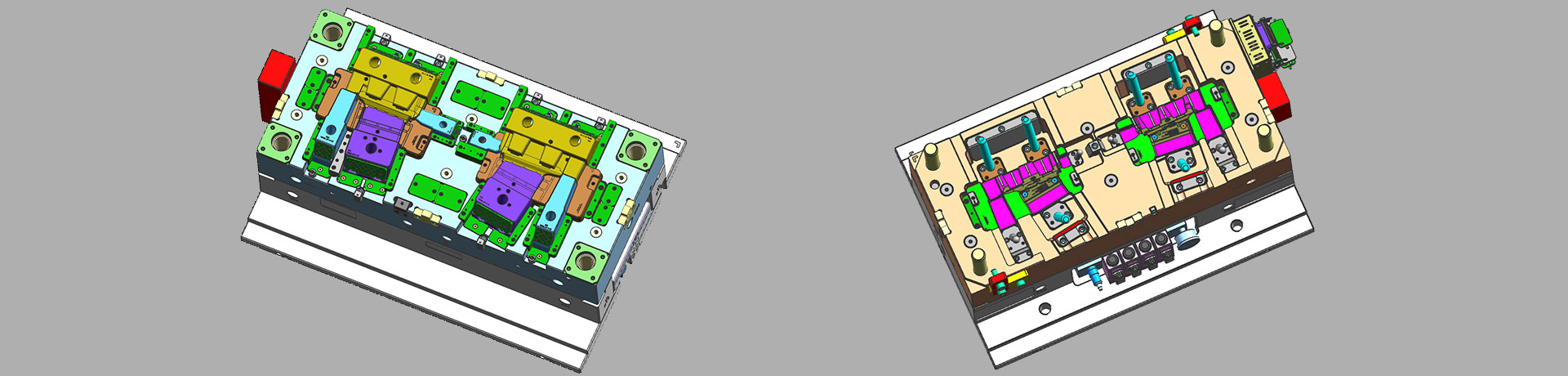

There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm machine and radiotube, the mold design and manufacturing way will be different comparing with the regular mold;

There are many advantages of vacuuming venting, but there are some tips should be paid attention:

- The vacuuming mold ill e e nin ot which can not connect w the air, all venting slot will be sealed by sealing ring to isolate from outside;

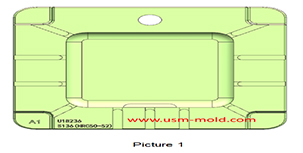

- There will be a sealing ring on the parting surface of the vacuuming mold ( as shown in pictur 1 ), its function is to isolate the connection between the cavitynd the outsid;

- Except for the connecton between the gate an the cavity the rest of the mold is sealed to prevent air from being carried out during vacuuming;

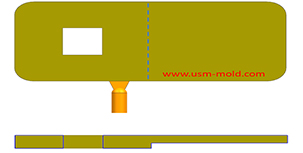

- All ejector pin and ejector rod should be sealed by sealing ring ( as shown in picture 2 );

- All the inserts and the bottom of the insertneed to be sealed by sealing ring;

- A vacuum solenoid valve control switch should be added to the mold;

- After the mold is closed, the vacuum system starts to pumping function before mold injection.

Popular USM Injection Molds

Related News about USM Injection Mold

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

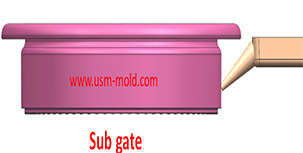

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Slider spring hength and strength calculation

Apr 22, 2024Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...view

English

English русский

русский