Blog

- 2001, 2022

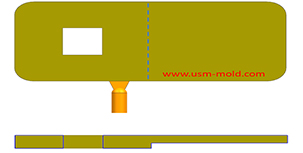

Direct gate of plastic injection mold runner system designTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More

Direct gate of plastic injection mold runner system designTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...More - 1801, 2022

Gate position determination of plastic injection mold runner design systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...More

Gate position determination of plastic injection mold runner design systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...More - 1701, 2022

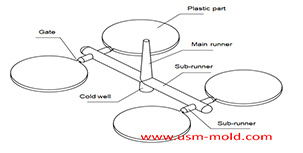

Plastic injection mold runner system designTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...More

Plastic injection mold runner system designTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...More - 1401, 2022

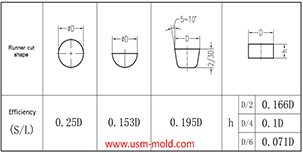

Hydraulic diameter conversion of runners in plastic mold gating system designTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...More

Hydraulic diameter conversion of runners in plastic mold gating system designTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...More - 1301, 2022

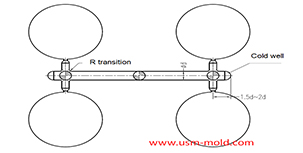

Key points of plastic injection mold runner systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More

Key points of plastic injection mold runner systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...More - 1201, 2022

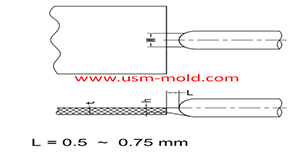

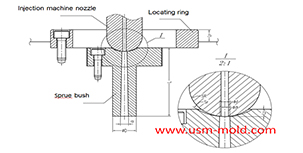

The main design points of the design of the plastic mold pouring systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...More

The main design points of the design of the plastic mold pouring systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...More - 1001, 2022

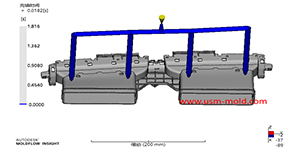

Plastic injection mold runner system design pointsTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...More

Plastic injection mold runner system design pointsTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...More - 701, 2022

Design principles of plastic injection mold runner systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More

Design principles of plastic injection mold runner systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |1. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...More

English

English русский

русский