Blog

- 1403, 2022

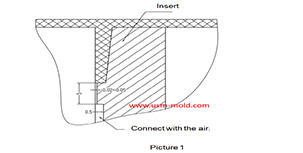

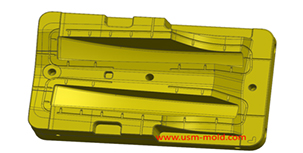

Venting insert design of molded partsTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...More

Venting insert design of molded partsTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...More - 1103, 2022

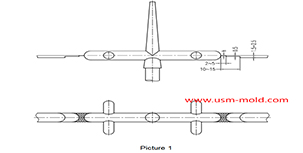

Parting surface venting of runner systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...More

Parting surface venting of runner systemTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...More - 803, 2022

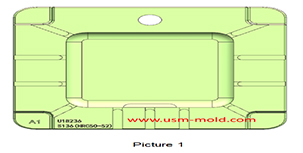

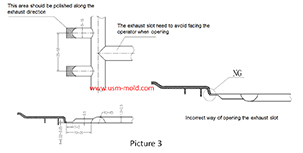

Venting of parting surfaceTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...More

Venting of parting surfaceTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...More - 703, 2022

The design principle of the exhaust slotTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...More

The design principle of the exhaust slotTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...More - 403, 2022

Design standard of exhaust slotTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More

Design standard of exhaust slotTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More - 303, 2022

The air trapping position in cavity and exhaust methodTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...More

The air trapping position in cavity and exhaust methodTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...More - 203, 2022

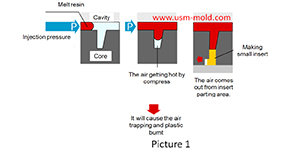

The main reasons for air trapping of plastic injecton moldTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...More

The main reasons for air trapping of plastic injecton moldTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...More - 102, 2022

Reasons for making the exhaust system of the injection moldTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...More

Reasons for making the exhaust system of the injection moldTags: Injection Mold | Injection Mold Supplier | Injection Mold Factory | Mold Factory | Mold Supplier | Injection Molding |The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...More

English

English русский

русский