TV bracket mold supplier

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Amazing Outdoor TravelingOur team experienced wonderful outdoor walking a few weeks ago. we took a big bus from our office to the destination which is very natural and frosty with a very clean river dotted with cobblestones. we walked through the small rivers by naked feet.More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Automotive Grille MoldThe part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.More+

Automotive Grille MoldThe part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.More+

Different treatment of plastic injection mold cooling system principlesDifferent treatment principle:1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be he...More+

Different treatment of plastic injection mold cooling system principlesDifferent treatment principle:1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be he...More+

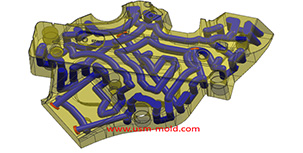

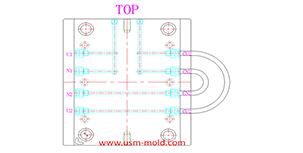

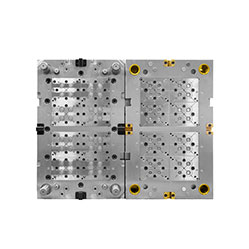

Multi Cavity Medical MoldMedical equipment products are divided into many different types, some products do not contact the human body, some contact the human body, some enter the body, and some products need to pass the FDA Alcohol test, some have to pass the FDA n-ethane test.More+

Multi Cavity Medical MoldMedical equipment products are divided into many different types, some products do not contact the human body, some contact the human body, some enter the body, and some products need to pass the FDA Alcohol test, some have to pass the FDA n-ethane test.More+

Gas-assisted Injection Molding EquipmentThe gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection ...More+

Gas-assisted Injection Molding EquipmentThe gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection ...More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Engine Coolant PipeIn the gas-assisted injection molding process, the gas always follows the path with the least flow resistance, from high pressure to low pressure, and flows to the thick wall part, because the temperature of this part is high and the resistance is small.More+

Gas & Water Assisted Injection MoldThe differences between water-assisted and gas-assisted molding1. Water-assisted injection molding uses water, and it can be recycled and reused, so the medium water of the two molding processes is cheaper than nitrogen.More+

Gas & Water Assisted Injection MoldThe differences between water-assisted and gas-assisted molding1. Water-assisted injection molding uses water, and it can be recycled and reused, so the medium water of the two molding processes is cheaper than nitrogen.More+

English

English русский

русский