TV bracket mold supplier

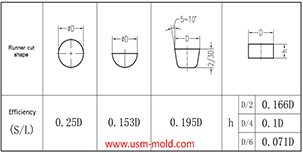

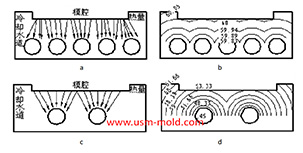

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

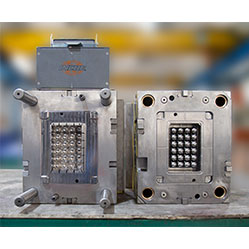

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

16 Cavities Plastic Injection MoldA 16-cavity multi cavity mold means that 16 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

Medical Plastic MoldProduct material: PP material in medical-gradeMold steel: S136 HRC 52-54Mold life: 1 millionHot runner brand: IncoeMold base: LKMSurface finishing: Mirror polishingMold lead time: 6 weeksMore+

Medical Plastic MoldProduct material: PP material in medical-gradeMold steel: S136 HRC 52-54Mold life: 1 millionHot runner brand: IncoeMold base: LKMSurface finishing: Mirror polishingMold lead time: 6 weeksMore+

Mold ManufacturingUSM is a one-stop service for plastic precision mold and injection molding factory in China, as we know, perfect molds are related to professional mold design, high precision processing machines, rich experiences assembling workers, and team management.More+

Mold ManufacturingUSM is a one-stop service for plastic precision mold and injection molding factory in China, as we know, perfect molds are related to professional mold design, high precision processing machines, rich experiences assembling workers, and team management.More+

What is Ejection Molding?The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short molding cycle and high production efficiency.More+

What is Ejection Molding?The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short molding cycle and high production efficiency.More+

PLC Controller Shell MoldMore and more people will have a high standard for a better life, most of home appliance product surfaces were made by mirror polishing, it requires for high standard to mold steel and polishing way, good mold steel without a technical polishing engineer, the product can not reach the high standard, they always work together.More+

PLC Controller Shell MoldMore and more people will have a high standard for a better life, most of home appliance product surfaces were made by mirror polishing, it requires for high standard to mold steel and polishing way, good mold steel without a technical polishing engineer, the product can not reach the high standard, they always work together.More+

New Five-axis CNC Machine ArrivalThe new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.GMU-6350 type CNC machining machineWorking stroke (XYZ): 630*500*550Maximum loading: 800kg...More+

New Five-axis CNC Machine ArrivalThe new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.GMU-6350 type CNC machining machineWorking stroke (XYZ): 630*500*550Maximum loading: 800kg...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

English

English русский

русский

_20250317101937A023.jpg)