Gas assisted injection product

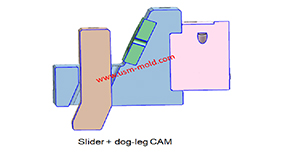

Classification of side parting and core pulling mechanismAccording to the structural characteristics, the side core-pulling mechanisms are divided into the following six categories:1. The side core-pulling mechanism of "slider + guide pin";2. The ...More+

Classification of side parting and core pulling mechanismAccording to the structural characteristics, the side core-pulling mechanisms are divided into the following six categories:1. The side core-pulling mechanism of "slider + guide pin";2. The ...More+

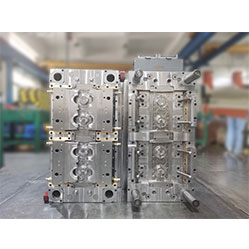

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Company ProfileUSM is one of the world's leading manufacturers of the plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automotive, High precision, and 2K...More+

Pre-deformation MoldThe main reasons to cause the plastic parts are warpage and deformation1. The uneven wall thickness of each part of the plastic product deforms. Usually, the main part of the product is thicker and the ribs are thin, when the plastic parts are cooled.More+

Pre-deformation MoldThe main reasons to cause the plastic parts are warpage and deformation1. The uneven wall thickness of each part of the plastic product deforms. Usually, the main part of the product is thicker and the ribs are thin, when the plastic parts are cooled.More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

Project ManagementThe project manager is the window for external communication and the bridge for the internal transmission of customer information in USM.More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

USM Purchased Two New Sodick Edm EquipmentsUSM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.More+

USM Purchased Two New Sodick Edm EquipmentsUSM purchased 2 new EDM Sodick equipment arrived a few months later, just finished the assembling and adjustment, we are very excited to see the processing soon with our new projects soon.More+

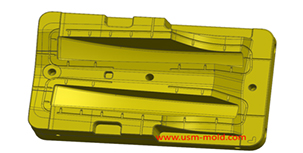

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Switch Cover Injection MoldThe K-type thermocouple is a metal thermocouple with strong oxidation resistance, which can measure the medium temperature of 0~1300℃, suitable for continuous use in oxidizing and inert gases, the short-term use temperature is 1200°C, and the long-term use temperature is 1000°C, the relationship between thermoelectric potential and temperature is approximately linear, and it is currently the biggest thermocouple.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

English

English русский

русский