gas assisted injection molding

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Design & EngineeringWe always insist that Design & Engineering is the core for mold, the USM engineering team will maintain communication closely with our customers at any time, from a project starting, they will participate in the customer's product design together.More+

Voice Operated Switch MoldWe know that the basic goal of smart home appliances is to provide people with a comfortable, safe, convenient and efficient living environment. Therefore, the most important thing for smart home appliance products is to take practicality as the core, remove those flashy functions, and use practicality, ease of use, and humanization.More+

Voice Operated Switch MoldWe know that the basic goal of smart home appliances is to provide people with a comfortable, safe, convenient and efficient living environment. Therefore, the most important thing for smart home appliance products is to take practicality as the core, remove those flashy functions, and use practicality, ease of use, and humanization.More+

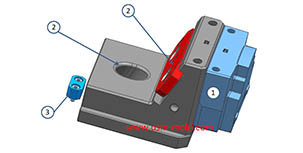

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

2022 Shenzhen Industrial Exhibition ITES ended successfullyThe 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen...More+

2022 Shenzhen Industrial Exhibition ITES ended successfullyThe 2022 ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 23rd Shenzhen International Machinery Manufacturing Exhibition were grandly opened in Shenzhen...More+

Mold AssemblingTo assemble the mold but not without fitting is the goal for every bench worker, and it has become the soul of every USM employee.More+

Mold AssemblingTo assemble the mold but not without fitting is the goal for every bench worker, and it has become the soul of every USM employee.More+

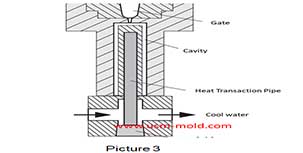

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

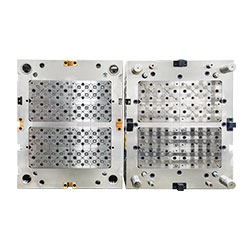

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

English

English русский

русский