gas assisted injection mold in China

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

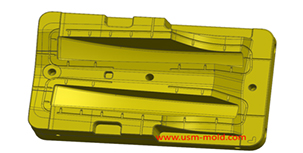

Automotive Door MoldThe plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.More+

Automotive Door MoldThe plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.More+

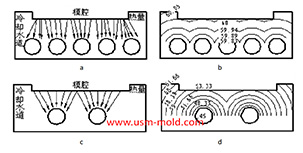

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

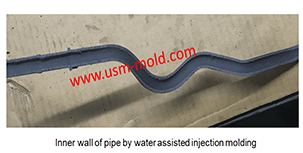

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

Comparison of water-assisted and gas-assisted injection moldingComparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid an...More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

32 Cavity MoldUSM has many years of experience in the design and manufacturing of multi-cavity molds and is particularly good at fast-selling products in medical and daily consumer products.More+

Plastic Box MouldThe operation way of smart home appliances is very diversified, It can be operated with a smart touch screen, a scene remote control, a mobile phone, or a computer. There is no limitation for time and place which can be operated at any time and any place, any devices realize intelligent control.More+

Plastic Box MouldThe operation way of smart home appliances is very diversified, It can be operated with a smart touch screen, a scene remote control, a mobile phone, or a computer. There is no limitation for time and place which can be operated at any time and any place, any devices realize intelligent control.More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

The design principle of the exhaust slotThe exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality...More+

Air Chamber MoldWith over 15 years of pre-deformed mold, USM Mold has mastered scientific and complete pre-deformation mold technology, from project management, mold flow analysis, design, manufacturing, assembling, mold trial, and final measurement.More+

Air Chamber MoldWith over 15 years of pre-deformed mold, USM Mold has mastered scientific and complete pre-deformation mold technology, from project management, mold flow analysis, design, manufacturing, assembling, mold trial, and final measurement.More+

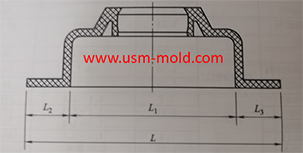

_20250317101937A023.jpg) What is the side parting and core pulling mechanisms with their function?When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...More+

What is the side parting and core pulling mechanisms with their function?When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...More+

English

English русский

русский

_20250317101516A021.jpg)