Automotive handle mold supplier

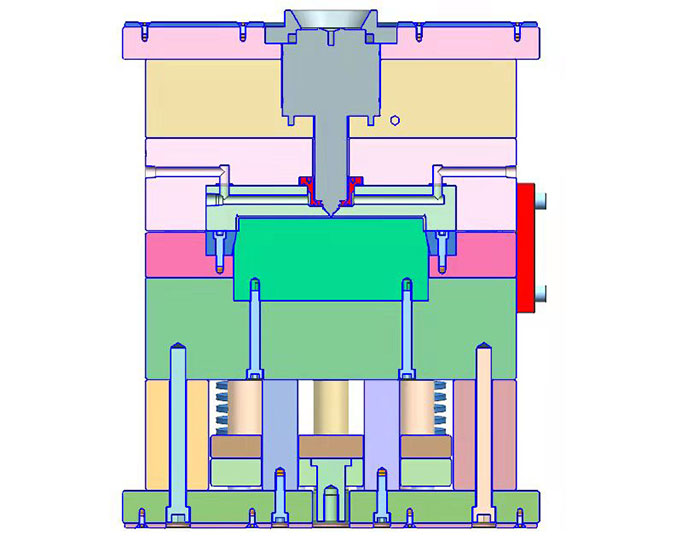

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

2K MoldThis mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.More+

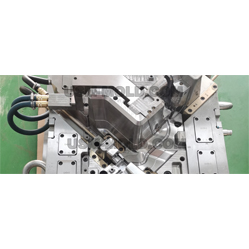

Automotive Mold SupplierWith over 15 years of experience in automotive mold development and production, USM will make mold flow analysis from the DFM report step to ensure that the pressure will be controlled at a reasonable range during injection, and there are no weld marks and other defects on the part surface.More+

Automotive Mold SupplierWith over 15 years of experience in automotive mold development and production, USM will make mold flow analysis from the DFM report step to ensure that the pressure will be controlled at a reasonable range during injection, and there are no weld marks and other defects on the part surface.More+

Cold Runner & Hot Runner Plastic MoldCommon Hot Runner Temperature Sensing Wires Types And CharacteristicsGenerally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensig wire is commonly known as the "thermocouple".More+

Cold Runner & Hot Runner Plastic MoldCommon Hot Runner Temperature Sensing Wires Types And CharacteristicsGenerally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensig wire is commonly known as the "thermocouple".More+

- USM makes a good job in mould industryProject management, manufacturing and engineering capabilities including project managerment solution, production design, development, mould and prototyping, material selection, manufacturingMore+

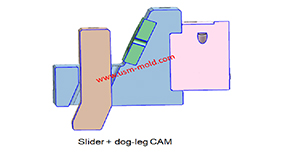

Classification of side parting and core pulling mechanismAccording to the structural characteristics, the side core-pulling mechanisms are divided into the following six categories:1. The side core-pulling mechanism of "slider + guide pin";2. The ...More+

Classification of side parting and core pulling mechanismAccording to the structural characteristics, the side core-pulling mechanisms are divided into the following six categories:1. The side core-pulling mechanism of "slider + guide pin";2. The ...More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

Plastic Pipe MoldThe booster pressurizes the nitrogen in the low-pressure storage cylinder into workable high-pressure nitrogen, and stores it in the high-pressure nitrogen cylinder, the maximum pressure of the nitrogen can reach 35MPa in the process.More+

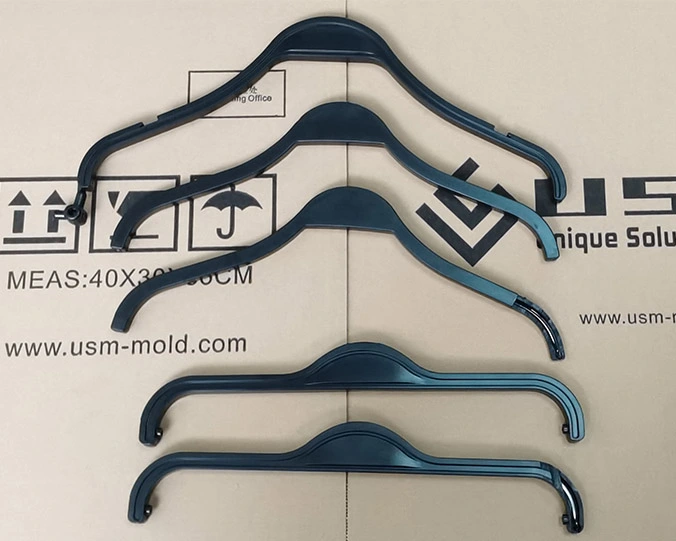

Gas-Assisted Injection Molding in Plastic HangersGas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weigh...More+

Gas-Assisted Injection Molding in Plastic HangersGas-assisted molding is a plastic injection molding technology that injects gas into the plastic in a molten state, forming a cavity inside the plastic, thereby achieving the purpose of reducing weigh...More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

English

English русский

русский