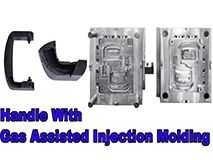

Automotive ceiling handle

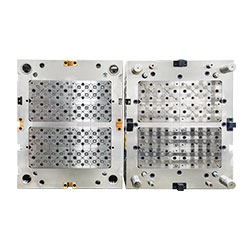

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

64 Cavities Plastic Injection MouldA 64-cavity multi-cavity mold means that 64 pieces of parts can be produced in one injection cycle at the same time, which can improve the production efficiency greatly, save production time and reduce production cost.More+

Automotive Fan MouldThe common products used to be water chambers, air chambers, engine inlet valve pipe and nylon connectors, and automotive AC systems: fan covers, fans, automotive brackets, sunroofs, mirror triangle brackets, automotive bottom sheets, and so on.More+

Automotive Fan MouldThe common products used to be water chambers, air chambers, engine inlet valve pipe and nylon connectors, and automotive AC systems: fan covers, fans, automotive brackets, sunroofs, mirror triangle brackets, automotive bottom sheets, and so on.More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

About UsUSM is one of the world's leading manufacturers of plastic injection mould and molded parts. We have always pushed developments forward and set benchmarks in Automtive, High precision and 2K moldi...More+

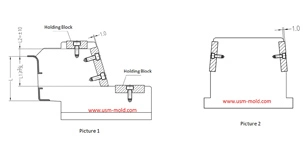

The design requirements of slider wear plate1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC;2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);3...More+

The design requirements of slider wear plate1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC;2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);3...More+

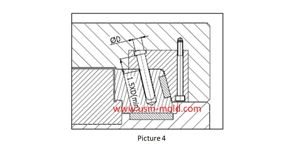

Slider spring hength and strength calculationProcessing size:1. ØD2=ØD+22. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2)Spring length calculation: (refer to picture 1 for length calculation)★L...More+

Slider spring hength and strength calculationProcessing size:1. ØD2=ØD+22. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2)Spring length calculation: (refer to picture 1 for length calculation)★L...More+

Plastic injection mold runner system designThe gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate dir...More+

Plastic injection mold runner system designThe gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate dir...More+

- Privacy PolicyThis Privacy Policy applies to the worldwide websites of which is part of the Sunkye International. It explains how we collect, process, share, secure and store personal information (information and ...More+

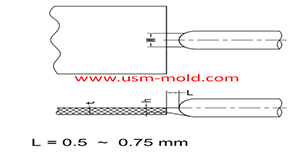

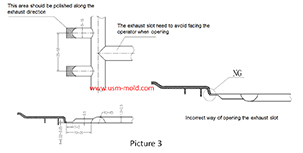

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

English

English русский

русский