Key points of gas-assisted injection molding process

Gas injection parameters

The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas injection pressure (MPa), the gas-assisted injection molding process is to inject the melt plastic into the mold and injecting high-pressure gas at the same time, there is a complicated two-phase interaction between the melt plastic and the gas, so the process parameter control is very important. The control method of each parameter as follows:

.png)

1. Injection volume

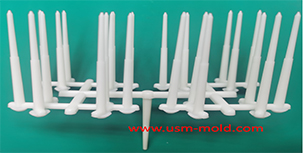

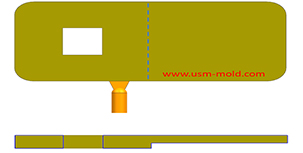

Gas-assisted injection molding uses the "short shot" method, that is a certain amount of material (usually 70-95% during full shot) is injected into the mold cavity and core, and then gas is injected to achieve a full filling process. The amount of melt injection has the big relationship with the gas channel of mold and the structure of the mold cavity with core, the larger the cross-section of the gas channel, the easier the gas to penetrate and the higher the hollowing rate, which is suitable for using a larger "short shot rate". If too much material is used at this time, melt accumulation is prone to occur, and sink marks will appear in places with a lot of material, if the material is too small, it will cause blow-through, if the direction of the gas channel and the flow material are exactly the same, it is most conducive to the penetration of the gas, and the hollowing rate of the air passage is the largest. So during the mold design, keep the gas channel and the flow direction in the same.

2. Injection speed and holding pressure

In the case of ensuring that the part performance without defective, use a higher injection speed as much as possible to make the melt fill the mold cavity with core as soon as possible, the melt plastic temperature remains high at this time, which is conducive to gas penetration and mold filling. The gas still maintains a certain pressure after pushing the melt to fill the mold cavity with core, which is equivalent to the pressure holding stage in traditional injection molding. generally speaking, the gas-assisted injection molding process can save the pressure holding process of the injection molding machine. Butsome parts still need to use certain injection molding pressure to ensure the part quality due to structural reasons. But do not use high holding pressure, because too high holding pressure will seal the gas needle, the gas in the cavity and core cannot be recovered, and it is easy to blow up when the mold is opened. High holding pressure will also hinder gas penetration, increasing the holding pressure of injection molding may cause larger sink marks in part surface.

3. Gas pressure and gas injection speed

The gas pressure has the big relationship with the fluidity of the material. Materials with good fluidity (such as PP) use lower gas injection pressure. The gas pressure is large which is easy to penetrate, but easy to blow through the part; the gas pressure is small, there may be insufficient mold filling, insufficient filling or sink marks on the part surfacet; the gas injection speed is high, and the mold can be filled when the melt temperature is high. For molds with long processes or small gas channel, increasing the gas injection speed is beneficial to the filling of the melt and can improve the part surface quality. However, if the gas injection speed in gas injection moulding process is too fast, blow-through may occur, and for parts with big gas channel, it may cause flow marks and gas mark on part surface.

4. Prolong time

The prolong time is the time from the injection starting of injection molding machine to the gas injection by the gas-assisted control part, which can be make as a parameter of the "synchronization" of the reverse mapping of the plastic and the gas injection. The prolong time is short, when the melt is still at a higher temperature, the gas injection is obviously better to gas penetration and mold filling, but if the prolong time is too short, the gas is easy to diverge, the hollowing shape is not good and the hollowing rate is also not enough.

Pin-point gate of plastic injection mold runner system design

Jan 24, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view_20250317091113A018.jpg)

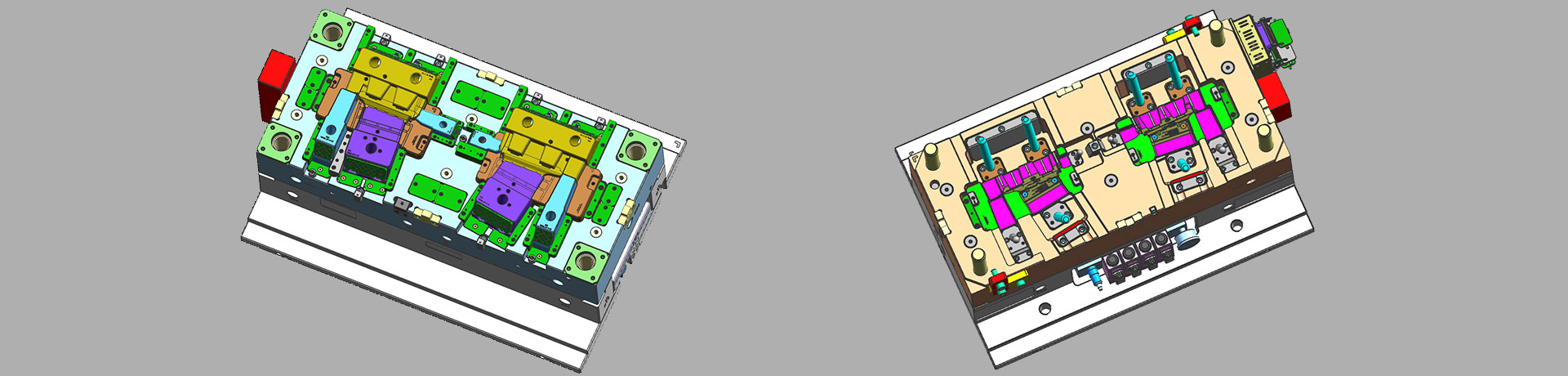

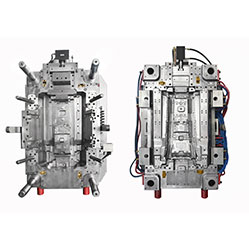

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

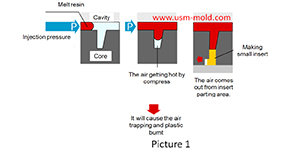

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view_20250317090912A017.jpg)

Several common process of water-assisted injection molding introduction

May 24, 2022According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...view

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

English

English русский

русский