Comparison of water-assisted and gas-assisted injection molding

Comparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid and the other is gaseous nitrogen, water is incompressible but gas does. The viscosity of water is higher than gas, and the thermal conductivity of water is 40 times than gas, the heat capacity is 4 times than gas. Although the theory of water-assisted and gas-assisted injection molding are the same, most technicians believe that water-assisted injection molding will not replace gas-assisted injectin molding,it depends on the application and mold.

.png)

The advantages of water-assisted injection molding and gas-assisted are as follows:

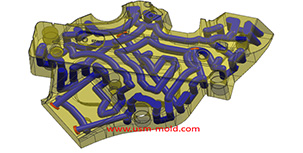

1. Shorten the cooling time of part significantly. Water-assisted injection molding is to inject high-pressure (30Mpa) water at a certain temperature (10~80℃) into the cavity and core, so the water can directly cool the product from the cavity and core of the product wall thickness, and this kind of cooling is sufficient cooling that acts uniformly from the inside to the outside of the product shape, and the effect is good, so the molding cycle of the product can be greatly shortened. Studies have shown that the cooling cycle time of water-assisted molding is only 25% or even lower than gas-assisted molding, for a product with a molding diameter of 10mm and a wall thickness of 1.0~1.5mm, the gas-assisted molding time is 60s, while the water-assisted molding time takes 15s; for a product with a molding diameter of 30mm and a wall thickness of 25-3.0mm, the gas-assisted molding time takes 180s, while the water-assisted molding time only needs 40s;

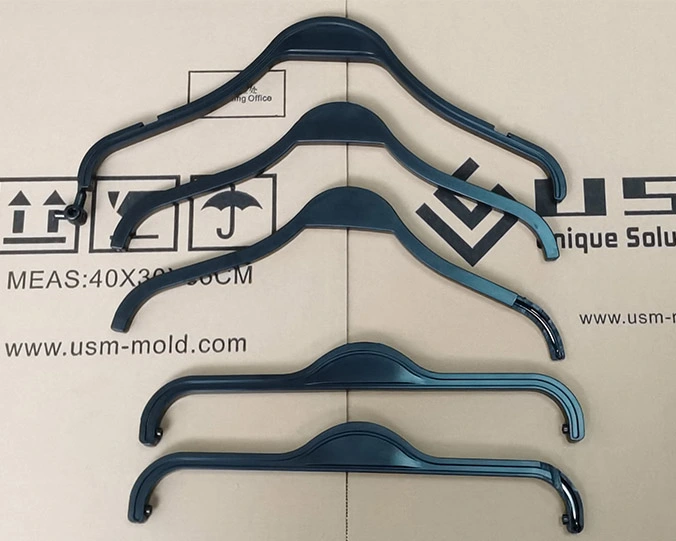

2. Make larger hollow section realized. Because water-assisted injection molding can be produced by two processes, the projectile method and the water injection method, the projectile method only needs to increase the diameter of the bullet to produce large-diameter hollow pipe products.

.png)

3. The inner wall is smooth, and also uven cooling makes the part deformation smaller. Since the water temperature used in water-assisted molding is much lower than the melt temperature, the interface between the water injected into the mold cavity with core side, and the high-temperature melt will immediately form a smooth, high-viscosity cured film due to the rapid decrease in the melt temperature, and solidify The water inside the membrane is uniformly pressed outward under the action of pressure, and the wall thickness of the product that has not been solidified is compressed and thinned, but the water will not penetrate the solidified membrane into the wall thickness, and the melt on the front side of the water flow is under the action of water pressure, moving forward makes more melt flow forward, so as to obtain a product with a thicker wall and a smooth inner surface;

4. The wall section is more even. During gas-assisted injection molding, due to the poor heat transfer and low cooling rate inside the cavity and core of the product, a coarser crystalline structure will be formed on the inside. On the contrary, when water-assisted injection molding, because of the good cooling effect of water on the inside, the internal structure of the product is similar to that of normal injection molding, that is the material structure in the product section is more symmetrical and the product has a smaller crystal phase structure.

5. The water cost is low and easy to get when using water assisted injection molding.

Potential disadvantages of water assisted injection moulding:

(1) Water leakage causes the mold to to rust and electronic components are prone to short circuits. Since the electronic components such as the hot runner and pressure sensor on the mold will short-circuit and burn out when they come into connect with water, water-assisted injection molding is easy to control due to the inability to control the pressure and water volume at the beginning of the debugging, it will cause water to flow to the mold and electronic components and cause damage to the electronic components, if the mold cavity and core side is often exposed to water, it will rust and cause the mold to be polished and maintained frequently;

(2) The water injection machine is in large size. Water-assisted injection molding equipment is much larger than gas-assisted equipment, and there are currently no mature water-assisted equipment manufacturers in China, and more mature and successful commercial equipment manufacturers are produced currently in Germany, and all equipment needs to be imported;

(3) The water-assisted process has bigger limitations than the gas assisted injection molding process, and it is not suitable for all parts;

(4)There are fewer materials for water-assisted injection molding, and new materials need to be developed specifically for water-assisted molding. Many materials need to be tested and improved many times before use. The earliest water-assisted molding plastic was developed by BASF. The PA66+GF30 is used to form the engine cooling manifold of Volkswagen’s EA888.

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

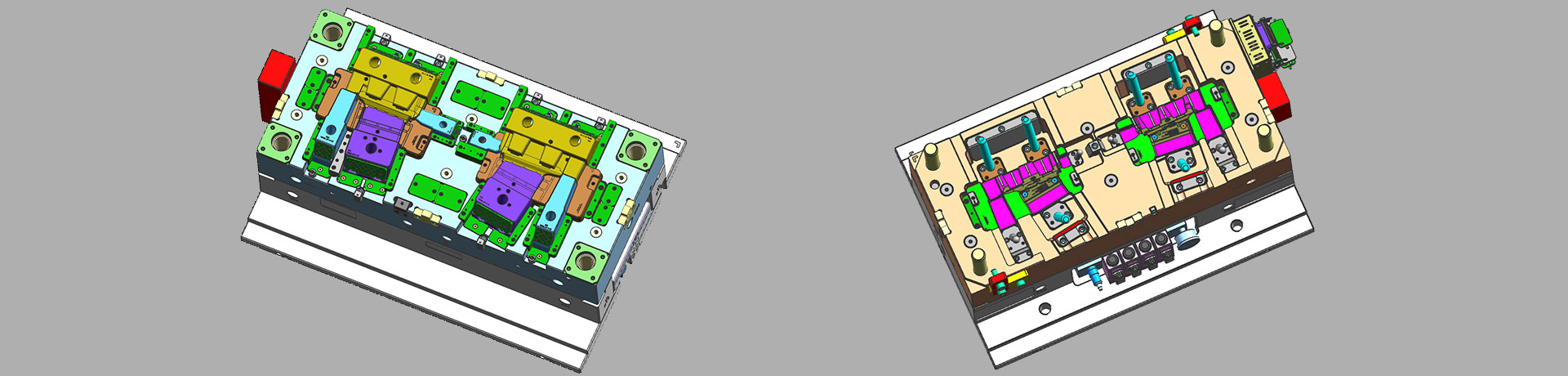

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

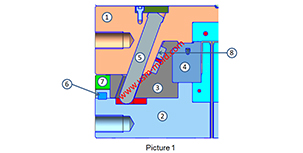

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

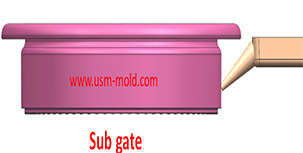

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

English

English русский

русский

_20250311083139A052.webp)