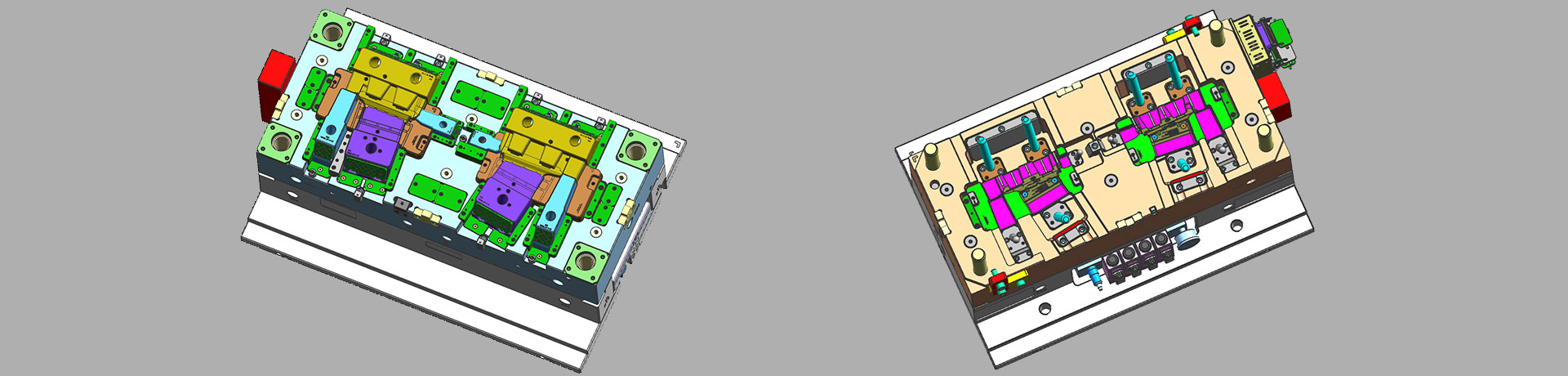

The principle of mold temperature balance in plastic mold cooling system design

The principle of mold temperature balance:

1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be make the mold temperature as balanced as possible, and there should be no local overheating or overcooling.

2. The high temperature areas in the mold including: near the sprue bushing, near the gate, and near the thick wall of the plastic part, these areas should be cooled.

3. Heating is sometimes required at thin-walled areas.

4. During the cooling process of the mold, due to the phenomenon of thermal expansion and contraction, the plastic part will slightly detach from the fixed mold cavity when the solid shrinks, while the tightening force on the core is getting bigger and biggger, and the plastic part is detaching, the more heat before demolding is transferred to the core, so the core must be focused on cooling.

5. To control the temperature difference of the cooling water at the inlet and outlet of the cooling channel, the temperature difference should be less than or equal to 2°C during precision injection molding, and in general, the temperature difference should be less than or equal to 5°C. the total length of the cooling gate (series length) should not be too long, preferably less than 1.5m, and the length of the dead zone should be as short as possible.

6. The cooling channel must be designed for the stripper in the three-plate mold, t, so that the mold temperature can be stabilized during the production process and the molding cycle can be shortened.

.png)

_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

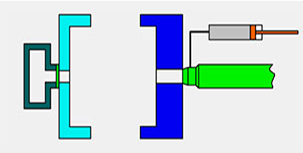

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

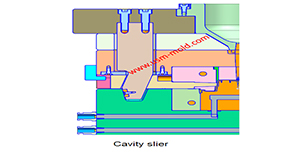

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

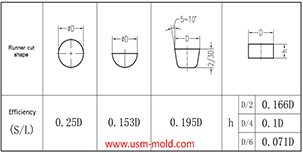

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

English

English русский

русский