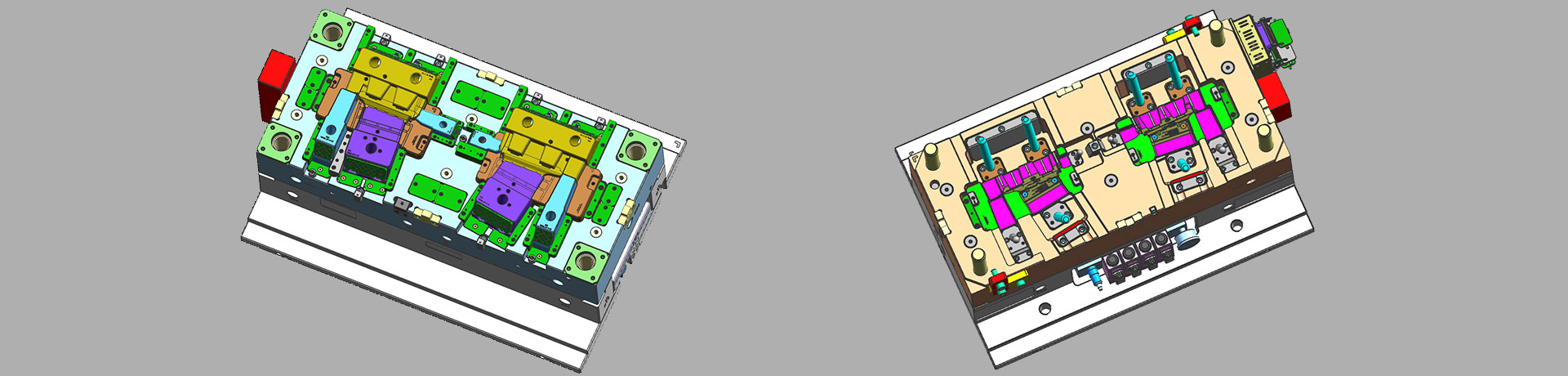

The design requirements of slider wear plate

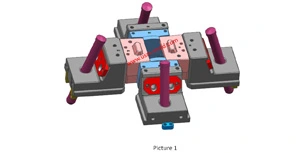

1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC;

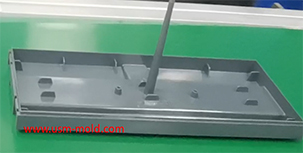

2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);

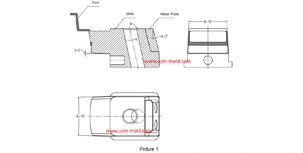

3. The minimum surface of the back wear plate is required to be more than 2/3 higher than the forming surface (see picture 1 L1≥2/3L);

4. The highest surface of the back wear plate is required to be ±10mm from the highest forming surface (see picture 1);

5. If the length and width of the slider are more than 100mm, in order to ensure that the force of the slider is uniform and does not shift after the mold is closed, the top surface of the slider must be designed with necessary parallel blocks (see picture 1);

6. When the side of the slider and the core side are inserted with a slope (see picture 2), the contact surface must be inserted with wear plate.

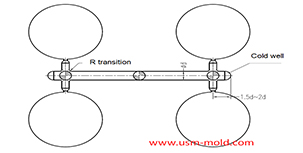

Key points of plastic injection mold runner system

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

Insert pin of vengting design for molded parts

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

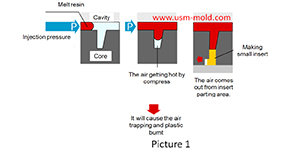

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

English

English русский

русский