The common fixing method of angle pin

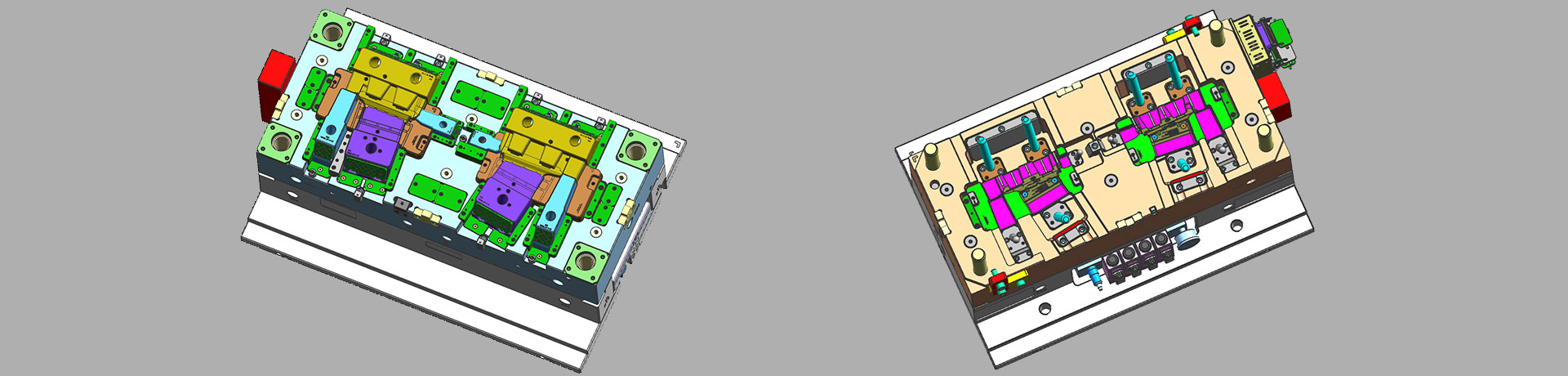

The angle pin is a common part of the drive slider, and the fixing and installation methods as following:

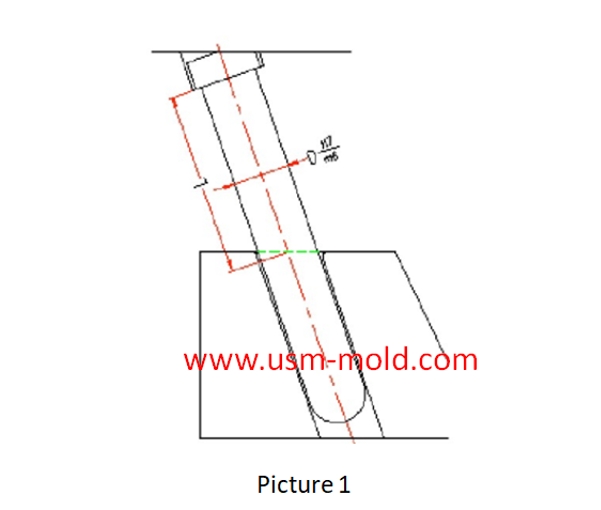

1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, as shown in picture 1.

This installation method is suitable for the case where the formwork is thin and the tope plate is not separated from the A plate, the matching surface is long and the stability is good, the matching tolerance of the angle pin and the fixed plate is H7/m6, disassembly and maintenance are very complex, the mold plate must be disaasembled when changethe angle pin.

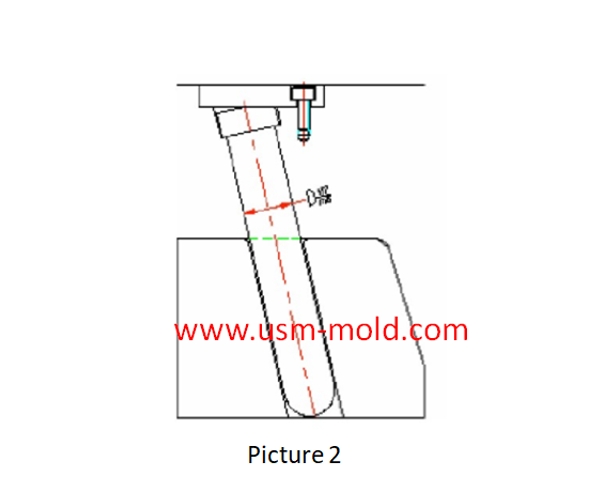

2. Pass through the template directly and press the angle pin with the pressing block to play a fixed role, as shown in picture 2.

This installation method is suitable for the case where the formwork is thin and the top plate is separated from the A plate, the matching surface is long and the stability is good, the matching tolerance of the angle pin and the fixed plate is H7/m6, installation and maintenance are very complex, and the plate must be disassembled to replace the angle pin.

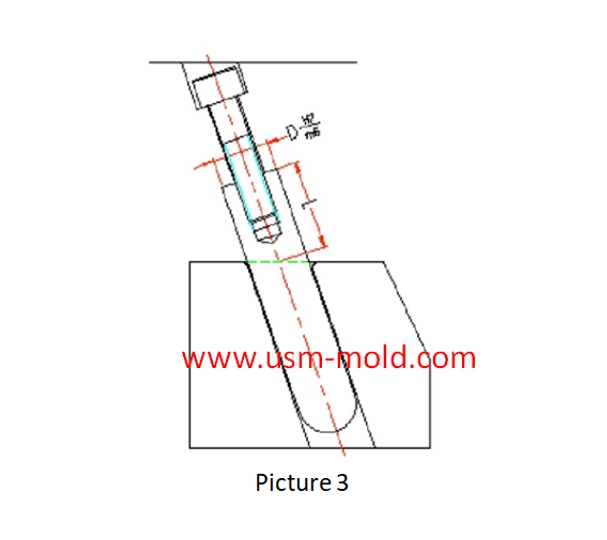

3. The angle pin does not pass through the plate, and the angle pint is still fixed on the plate, but the hole for fixing theangle pin is a blind hole, and a screw is used at the back to tighten the angle pin, this kind of angle pin has no steps, as shown in picture 3.

This installation method is suitable for use in the case of thick plate, and both two-plate and three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has poor stability, and is difficult to process and maintain in the future.

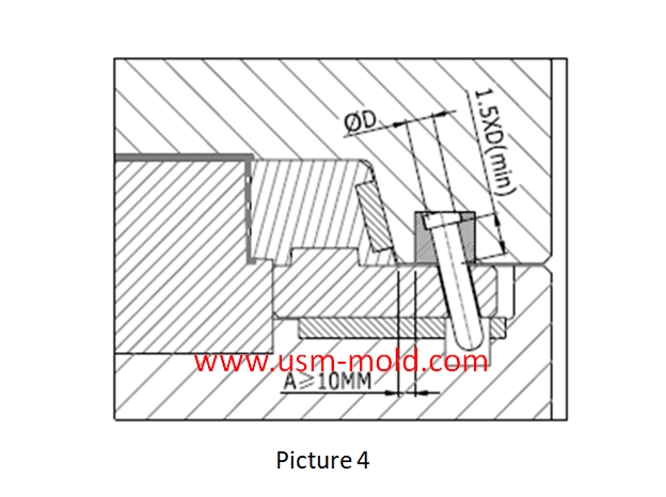

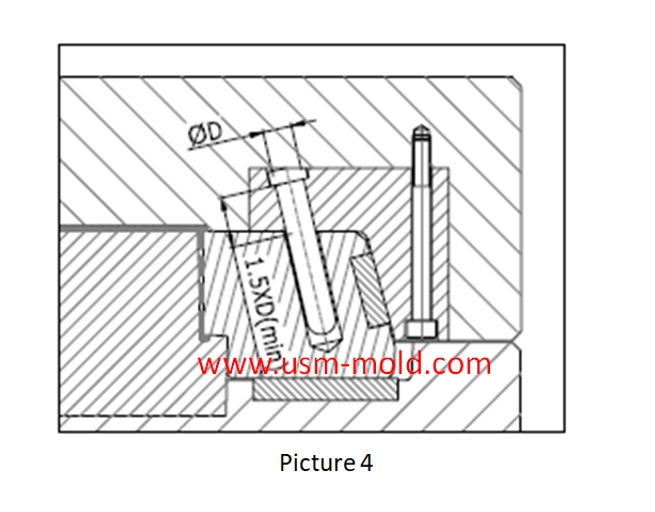

4. The angle pin is not installed in the plate, but is installed in a movable block which is fixed to the plate from the front with screws, the movable block can be disassembled from the front of the plltae, see the picture 4.

This installation method is suitable for use in the case of thick plate, both two-plate with three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has good stability, and is very convenient for processing and maintenance, it is a more common used installation method.

5. The angle pin is not installed in the plate, but is installed in the locking block, this locking block is fixed to the plate from the front with screws, the locking block can be disassembled from the front of the plate, as shown in picture 5.

This installation method is suitable for use in the case of thick plate, both two-plate and three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has good stability, and is very convenient for processing and maintenance, it is also a more common used installation method.

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

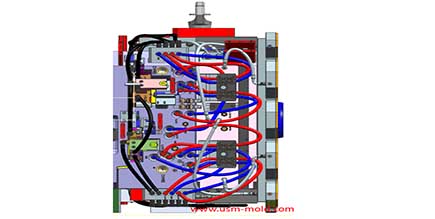

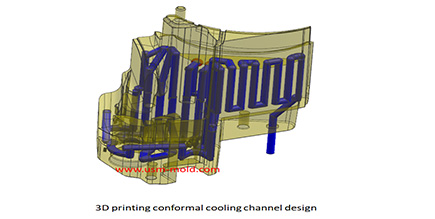

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

English

English русский

русский

_20250310164515A048.webp)