The air trapping position in cavity and exhaust method

The air trapping in cavity is usually in the following places:

1. Thin-wall structure cavity, the end of melt flow;

2. The junction of two or more melts;

3. The last area where the melt in the cavity reaches;

4. The bottom of the blind hole of the mold cavity is mostly the end of a solid column in the part;

5. Reinforcing ribs of molded parts and the bottom of screw pillars;

6. Dead corners of complex mold cavities.

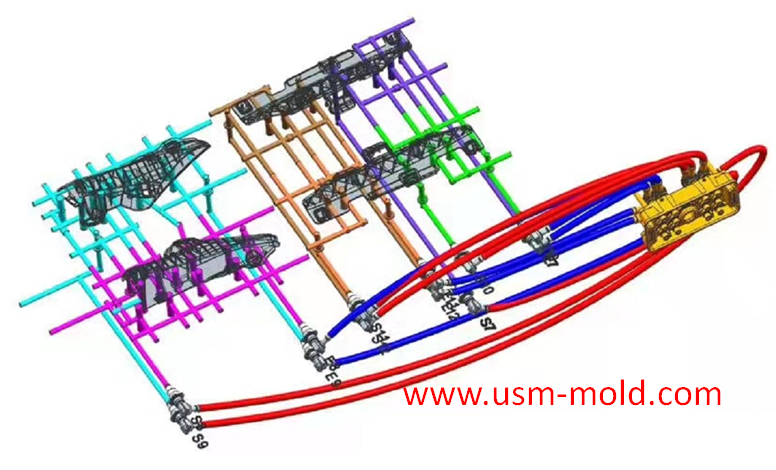

.png)

Exhaust method in injection mold include as following:

1. Parting surface (including venting slot);

2. The fitting surface of insert;

3. The fitting surface of the push rod or pipe with inner mold insert;

4. Exhaust from side core pulling mechanism;

5. Add a vent needle or insert to vent the air in the trapped area;

6. Breathable steel exhaust;

7. Air valve exhaust;

8. The mold is evacuated and exhausted.

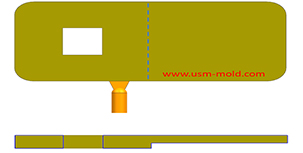

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

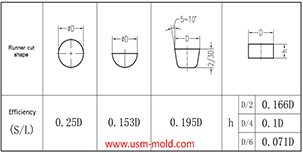

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

Reasons for making the exhaust system of the injection mold

Feb 28, 2022The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...view

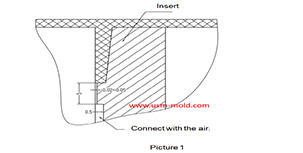

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view

English

English русский

русский