TV bracket mold supplier

New Five-axis CNC Machine ArrivalThe new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.GMU-6350 type CNC machining machineWorking stroke (XYZ): 630*500*550Maximum loading: 800kg...More+

New Five-axis CNC Machine ArrivalThe new 5 axis CNC machining machine has arrived in our workshop on 6th Nov. 2021 and is now putting into use.GMU-6350 type CNC machining machineWorking stroke (XYZ): 630*500*550Maximum loading: 800kg...More+

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

Venting insert design of molded partsIn the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw colu...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

Multi Cavities Hot Runner Injection MoldThe hot runner will keep the plastic material in liquid in runner and injection gate, the temperature in injection machine barrel and runner are very high which can keep the material in liquid, due to there is heating system surrounded, it will only need to heat the hot runner to request temperature before production, and the hot runner is like the extension of injection machine barrel.More+

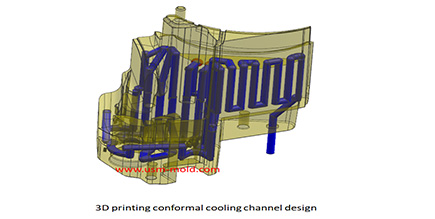

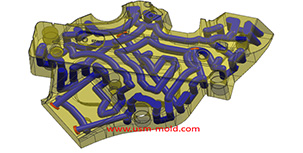

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

Design principle of plastic injection mold cooling systemDesign principle of cooling systemIn order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in the...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

Plastic cooling factors by injection parameter1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately pro...More+

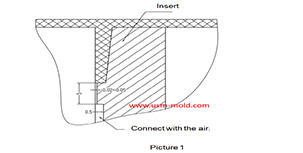

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

Insert pin of vengting design for molded partsInsert pin of venting:It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end ...More+

English

English русский

русский