Mold Supplier

Controling method of plastic injection mold temperatureExcept for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat condu...More+

Controling method of plastic injection mold temperatureExcept for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat condu...More+

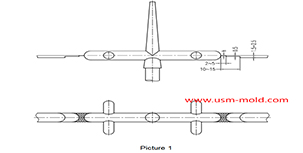

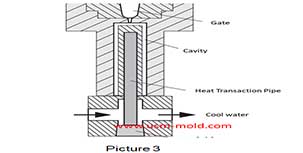

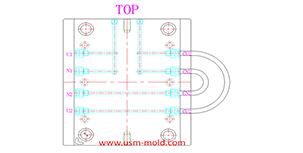

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

Plastic injection mold common cooling gate1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. ...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

The principle of mold temperature balance in plastic mold cooling system designThe principle of mold temperature balance:1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be mak...More+

Different treatment of plastic injection mold cooling system principlesDifferent treatment principle:1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be he...More+

Different treatment of plastic injection mold cooling system principlesDifferent treatment principle:1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be he...More+

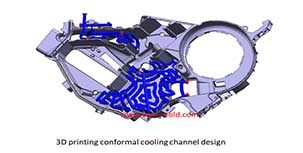

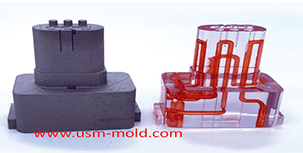

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

Conformal cooing channel of plastic injection moldThe conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product wel...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

Reasons for making the exhaust system of the injection moldThe gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in hi...More+

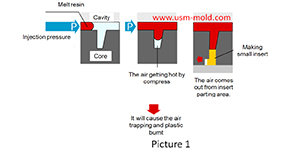

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

The air trapping position in cavity and exhaust methodThe air trapping in cavity is usually in the following places:1. Thin-wall structure cavity, the end of melt flow;2. The junction of two or more melts;3. The last area where the melt in the cavity rea...More+

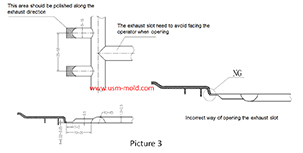

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

English

English русский

русский