Gas assisted injection product

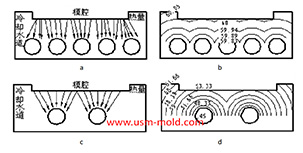

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

Factors affecting the cooling rate of parts by injection moldingIt should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature ...More+

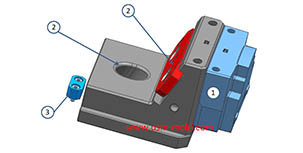

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

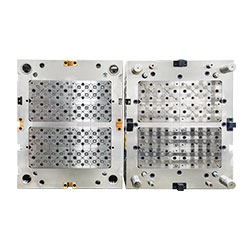

Medical TPE MoldSince the establishment of the factory, USM has provided injection molding products and injection mold services for many medical companies around the world, especially in medical multi-cavity and small products (pipetting tips) with rich and valuable experience.More+

Medical TPE MoldSince the establishment of the factory, USM has provided injection molding products and injection mold services for many medical companies around the world, especially in medical multi-cavity and small products (pipetting tips) with rich and valuable experience.More+

Dongguan International Machine Tool Exhibition of 2021 hedling successfully2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry.More+

Dongguan International Machine Tool Exhibition of 2021 hedling successfully2021 is an extraordinary year, although the epidemic has not completely subsided, it cannot stop the enthusiastic pursuit of new equipment and new technologies in the Chinese manufacturing industry.More+

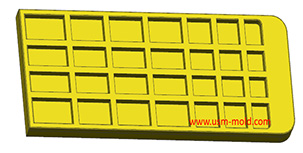

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

Plastic part ribs desiginingThe ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of t...More+

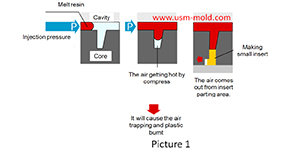

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

The main reasons for air trapping of plastic injecton moldDuring the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.The mechanism of air trapped...More+

Drip Tip MoldThe two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.More+

Drip Tip MoldThe two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.More+

English

English русский

русский