gas assisted injection molding process

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

Slider designing tips 11. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially lengt...More+

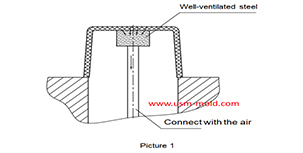

Well-ventilated steel of venting design for molded partsWell-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow th...More+

Well-ventilated steel of venting design for molded partsWell-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow th...More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

PA66 GF30 Car Parts Plastic Injection MoldPre-deformation means that the product will be designed mold in opposite direction in advance. The product is injected and cooled by natural shrinkage, the two deformations will be offset to obtain a product and meet the drafting tolerance.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

Cold Runner MouldCompared with the hot runner mold, a cold runner mold does not require a special heating system for the runner system. It will be cooled with the product together and taken out after injection finishing, and then cut the runner, the cold runner mold is what we often call the traditional mold.More+

8 Cavity MoldAs a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.More+

8 Cavity MoldAs a medical plastic injection mold supplier, It has its own unique solutions from medical product development to mold design, mold manufacturing, and injection molding production.More+

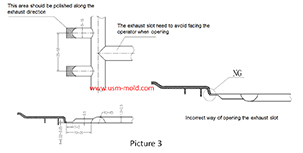

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

Design standard of exhaust slotThe exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...More+

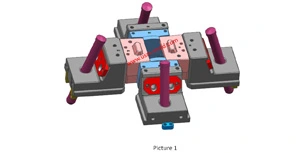

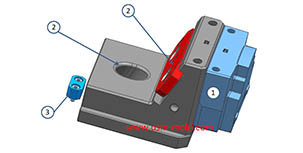

The T slot of slider and guider designing tips1. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will ...More+

The T slot of slider and guider designing tips1. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will ...More+

English

English русский

русский